6. Procedure

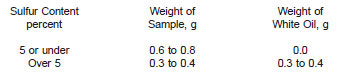

6.1 Preparation of Bomb and Sample - Cut a piece of firing wire 100 mm in length. Coil the middle section (about 20 mm) and attach the free ends to the terminals. Arrange the coil so that it will be above and to one side of the sample cup. Insert between two loops of the coil a wisp of cotton or nylon thread of such length that one end will extend into the sample cup. Place about 5 mL of Na2CO3 solution in the bomb (Note 2) and rotate the bomb in such a manner that the interior surface is moistened by the solution. Introduce into the sample cup the quantities of sample and white oil (Note 3 and Note 4) specified in the following table, weighing the sample to the nearest 0.2 mg (when white oil is used, stir the mixture with a short length of quartz rod and allow the rod to remain in the sample cup during the combustion).

NOTE 2 - After repeated use of the bomb for sulfur determinations, a film may be noticed on the inner surface. This dullness can be removed by periodic polishing of the bomb. A satisfactory method for doing this is to rotate the bomb in a lathe at about 300 rpm and polish the inside surface with emery polishing papers Grit No. 2/0 , or equivalent paper, coated with a light machine oil to prevent cutting, and then with a paste of grit-free chromic oxide and water. This procedure will remove all but very deep pits and put a high polish on the surface. Before the bomb is used it shall be washed with soap and water to remove oil or paste left from the polishing operation.

6.1.1 Warning - Do not use more than 1.0 g total of sample and white oil or other low sulfur combustible material or more than 0.8 g if the IP 12 bomb is used.

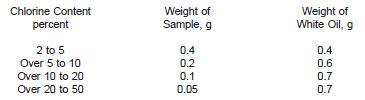

NOTE 3 - Use of sample weights containing over 20 mg of chlorine may cause corrosion of the bomb. To avoid this, it is recommended that for samples containing over 2 % chlorine, the sample weight be based on the chlorine content as given in the following table:

NOTE 4 - If the sample is not readily miscible with white oil, some other low sulfur combustible diluent may be substituted. However, the combined weight of sample and nonvolatile diluent shall not exceed 1.0 g or more than 0.8 g if the IP 12 bomb is used.

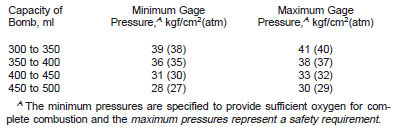

6.2 Addition of Oxygen - Place the sample cup in position and arrange the cotton wisp or nylon thread so that the end dips into the sample. Assemble the bomb and tighten the cover securely. (Warning - Do not add oxygen or ignite the sample if the bomb has been jarred, dropped, or tilted.) Admit oxygen slowly (to avoid blowing the oil from the cup) until a pressure is reached as indicated in the following table:

6.3 Combustion - Immerse the bomb in a cold distilled-water bath. Connect the terminals to the open electrical circuit. Close the circuit to ignite the sample. (Warning - Do not go near the bomb until at least 20 s after firing.) Remove the bomb from the bath after immersion for at least 10 min. Release the pressure at a slow, uniform rate such that the operation requires not less than 1 min. Open the bomb and examine the contents. If traces of unburned oil or sooty deposits are found, discard the determination and thoroughly clean the bomb before again putting it in use (Note 2).

6.4 Collection of Sulfur Solution - Rinse the interior of the bomb, the oil cup, and the inner surface of the bomb cover with a fine jet of water, and collect the washings in a 600-mL beaker having a mark to indicate 75 mL. Remove any precipitate in the bomb by means of a rubber policeman. Wash the base of the terminals until the washings are neutral to the indicator methyl red. Add 10 mL of saturated bromine water to the washings in the beaker. (The volume of the washings is normally in excess of 300 mL.) Place the sample cup in a 50-mL beaker. Add 5 mL of saturated bromine water, 2 mL of HCl, and enough water just to cover the cup. Heat the contents of the beaker to just below its boiling point for 3 or 4 min and add to the beaker containing the bomb washings. Wash the sample cup and the 50-mL beaker thoroughly with water. Remove any precipitate in the cup by means of a rubber policeman. Add the washings from the cup and the 50-mL beaker, and the precipitate, if any, to the bomb washings in the 600-mL beaker. Do not filter any of the washings, since filtering would remove any sulfur present as insoluble material.

6.5 Determination of Sulfur - Evaporate the combined washings to 200 mL on a hot plate or other source of heat. Adjust the heat to maintain slow boiling of the solution and add 10 mL of the BaCl 2 solution, either in a fine stream or dropwise. Stir the solution during the addition and for 2 min thereafter. Cover the beaker with a fluted watch glass and continue boiling slowly until the solution has evaporated to a volume approximately 75 mL as indicated by a mark on the beaker. Remove the beaker from the hot plate (or other source of heat) and allow it to cool for 1 hr before filtering. Filter the supernatant liquid through an ashless, quantitative filter paper (Note 5). Wash the precipitate with water, first by decantation and then on the filter, until free from chloride. Transfer the paper and precipitate to a weighed crucible and dry (Note 6) at a low heat until the moisture has evaporated. Char the paper completely without igniting it, and finally ignite at a bright red heat until the residue is white in color. After ignition is complete, allow the crucible to cool at room temperature, and weigh.

NOTE 5 - A weighed porcelain filter crucible (Selas type) of 5 to 9-µm porosity may be used in place of the filter paper. In this case the precipitate is washed free of chloride and then dried to constant weight at 500 more or less 25°C.

NOTE 6 - A satisfactory means of drying, charring, and igniting the paper and precipitate is to place the crucible containing the wet filter paper in a cold electric muffle furnace and to turn on the current. Drying, charring, and ignition usually will occur at the desired rate.

6.6 Blank - Make a blank determination whenever new reagents, white oil, or other low-sulfur combustible material are used. When running a blank on white oil, use 0.3 to 0.4 g and follow the normal procedure.