TEST METHOD A - ETHYLBENZENE AND TOTAL AROMATICS CONTENTS BY MEANS OF A SINGLE PACKED COLUMN GAS CHROMATOGRAPHIC ANALYSIS

5. Apparatus

5.1 Chromatograph, any gas chromatographic instrument that has the following performance and characteristics:

5.1.1 Sensitivity - The overall sensitivity must be sufficient to detect 0.1 volume % of any aromatic compound of interest with a peak height of at least 10 % of full-scale chart deflection without loss of resolution as defined in 5.1.2, or 10 times the noise level.

5.1.2 Column - Any column and conditions may be used provided the system meets all the following criteria when the test blend is injected into the chromatograph and the chromatogram recorded in accordance with 7.2, is analyzed as follows:

5.1.2.1 Construct tangents to the peak to intersect the baseline for the n-tridecane (nC13) and toluene peaks. Measure the distance between the two peaks and the width of each peak as the distance along the baseline under the peak between the points of intersection (see Fig. 1).

5.1.2.2 Calculate the peak resolution,

R = 2Δd/(Y1 + Y2)

where:

Δd = distance between nC13 and toluene peaks,

Y1 = width of nC13 peak along the baseline, and

Y2 = width of the toluene peak along the baseline.

The peak resolution, R, must be not less than 0.9, otherwise the resolution of ethylbenzene may be lost.

NOTE 2 - The selectivity of the column (separation of the nonaromatics from aromatics) can be increased by increasing the concentration of liquid phase or by increasing the temperature of the chromatographic column. The resolution of the aromatic compounds can be improved by increasing the length of the column or by decreasing the oven temperature or inlet pressure of the carrier gas.

5.1.2.3 Ethylbenzene must be separated from paraxylene and isopropylbenzene or from paraxylene plus isopropylbenzene with the depth of the valley after ethylbenzene not less than 50 % of the ethylbenzene peak height.

5.1.2.4 The system must measure durene with a peak height of at least 10 % of full scale chart deflection or at least 10 times the noise level.

NOTE 3 - A combination of column materials and conditions that has been found to be particularly suitable for this test method is listed in Table 1. Such column may be obtained from most chromatography supply houses that offer packed GC columns.

5.2 Strip Chart Recorder Integrator - A recording potentiometer with a fullscale deflection of 10 mV or less should be used. If manual integration, such as triangulation, paper cut-out or planimeter, is employed the chart speed should be at least 1.5 m/h (60 in./h) in order to minimize errors in peak area measurement. This is not necessary where a ball-and-disk or an electronic integrator is employed.

5.3 Micro Syringe - A 10-µL micro syringe for specimen introduction.

6. Reagents and Materials

6.1 Aromatic Hydrocarbons - Toluene, ethylbenzene, paraxylene, isopropylbenzene (cumene), 1,2,4-trimethylbenzene (pseudocumene), and 1,2,4,5-tetramethylbenzene (durene) 99.5 mol % minimum.

6.2 Carrier Gas (Note 3).

6.3 Internal Standard - Cyclohexanone, 99.5 mol % minimum (see 1.6).

6.4 Chromatographic Column (Note 3).

6.5 Normal Paraffin - n-Tridecane, 99.5 mol % minimum.

6.6 Solid Support (Note 3).

6.7 Paraffin Solvent for Test Blend - n-Hexane, n-heptane, or iso-octane 99 mol % minimum.

7. Calibration

7.1 Preparation of Test Blend - Prepare a test blend to evaluate the sensitivity and resolution of the equipment and test procedure. To do this, pipet the exact volume of each hydrocarbon indicated in Table 2 into a 100-mL volumetric flask. Fill to the 100-mL mark with one of the solvents listed in 6.7 and mix by inverting several times. See 1.6.

NOTE 4 - Durene is a solid. In preparing the test blend, the quantity of durene required should be weighed, using as its density 0.8875 g/mL.

7.2 Select the instrument conditions and specimen size so as to give the necessary sensitivity and resolution. Inject the test blend into the column at these conditions. Change the attenuation, if necessary, so that the internal standard and aromatic peaks are measured with a chart deflection of not less than 25 % nor more than 95 % of full scale for attenuated peaks. Check the column performance against the requirements given in 5.1.2.

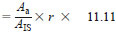

7.3 Response Factor - Assume that the aromatics in the sample have the same relative response as pseudocumene in the test blend. Using the results from the test blend, calculate the response factor as follows:

where:

r = relative response factor for aromatics,

AIS = area of the internal standard peak in arbitrary units corrected for attenuation,

VIS = volume % of the internal standard in the blend,

Aa = area of the pseudocumene peak in arbitrary units corrected for attenuation, and

Va = volume % of pseudocumene in the blend.

8. Procedure

8.1 Using the exact instrument conditions as were used in the calibration, inject the test material. Inspect the chromatogram to determine that there is complete resolution between the saturated and the aromatic peaks.

8.2 Pipet exactly 1.0 mL of cyclohexanone internal standard into a 10-mL volumetric flask. Fill to the mark with the sample and mix by inverting several times.

8.3 With the exact instrumental conditions used in the calibration, inject the same volume of sample containing the internal standard. Change the attenuation, if necessary, so as to measure the area of the internal standard and aromatic peaks with not less than 25 % nor more than 95 % chart deflection on attenuated peaks.

9. Calculation

9.1 Measure the areas of all aromatic and internal standard peaks. Use of an electronic integrator is recommended to obtain the best accuracy and precision.

NOTE 5 - Because the C8 and heavier aromatic compounds may not be completely resolved, peak height multiplied by one half width or retention time must not be used as a means of measuring the area.

9.2 If a different attenuation is used for part of the chromatogram, correct to a constant attenuation basis by multiplying the area of the aromatic peaks by the ratio:

Sa/Ss

where:

Ss = attenuation sensitivity used for the internal standard peak and

Sa = attenuation sensitivity used for the aromatic peak.

9.3 Calculate the concentrations of ethylbenzene and C8 and heavier aromatics as follows:

Va = (Aa x r x 10)/(AIS x 0.9)

where:

Va = volume % of the aromatic compound(s),

Aa = area of the aromatic peak(s) corrected to a constant attenuation,

r = relative response factor for the aromatic compounds,

10 = volume % of internal standard,

AIS = area of the internal standard peak, and

0.9 = factor to correct for the dilution by the internal standard.

9.4 Total Aromatics - Add the amounts of the aromatic compounds found to obtain the volume percent of total aromatics in the sample.

10. Report

10.1 Report the following information: concentrations of ethylbenzene, total aromatics, and C8 plus higher aromatics (except ethylbenzene) in volume percent to the nearest 0.1 %.

11. Precision and Bias

11.1 The precision estimates are based on an interlaboratory study on four samples, containing approximately 6.5, 8.5, 11.8, and 16.5 % total aromatics and 0.0, 1.0, 4.0, and 0.3 % ethylbenzene. One analyst in each of six laboratories performed duplicate determinations on different days, for a total of 48 determinations of total aromatics content and 48 determinations of ethylbenzene content. The within-laboratory coefficient of variation was found to be 1.7 % relative with 23 df, and the between-laboratories coefficient of variation was 4.4 % relative with 5 df. Based on these coefficients the following criteria should be used for judging the acceptability of results at the 95 % confidence level.

11.1.1 Repeatability - Two results obtained by the same operator on different days should be considered suspect if they differ by more than 5 % relative.

11.1.2 Reproducibility - Two results obtained by operators in different laboratories should be considered suspect if they differ by more than 16 % relative.

11.2 Bias - There was no statistically significant bias of the results compared with expected values for quantitatively prepared standards. Hence, the determination of total aromatics in mineral spirits by packed column gas chromatography as described in this test method has no bias.