6. Apparatus

6.1 Four-Ball Wear Test Machine - See Figs. 1-3.

NOTE 3 - It is important to distinguish between the Four-Ball E.P. and the Four-Ball Wear Test Machines. The Four-Ball E.P. Test Machine is designed for testing under heavier loads and lacks the sensitivity necessary for wear tests.

6.2 Microscope, capable of measuring the diameters of the scars produced on the three stationary balls to an accuracy of 0.01 mm. It is more efficient to measure the scars without removing the three balls from the holder.

7. Materials

7.1 Test Balls, chrome alloy steel, made from AISI standard steel No. E-52100, with diameter of 12.7 mm [0.5 in.] Grade 25 EP (Extra Polish). Such balls are described in ANSI B3.12. The extra-polish finish is not described in that specification. The Rockwell C hardness shall be 64 to 66, a closer limit than is found in the ANSI requirement.

7.2 Cleaning Fluids for preparing balls and apparatus for the test should be those approved as nontoxic, capable of removing antirust coatings from the balls, eliminating test-oil carryover from one test to the next, and not contribute to wear or antiwear of the test lubricant. When the fluid(s) is flammable, appropriate precautions should be taken (see Note 1). In the round-robin tests to determine repeatability and reproducibility no specific directions were given for cleaning balls and machine parts. Operators reported using various solvents with and without a sonic cleaning bath. Cleaning techniques reported by some cooperators are included in Research Report RR: D02-1152, see Note 4.

8. Test Conditions

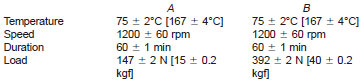

8.1 The test conditions used to develop the precision data as stated in Section 10 were:

9. Preparation of Apparatus

9.1 Set up the drive of the machine to obtain a spindle speed of 1200 more or less 60 rpm.

9.2 Set temperature regulator to produce a test-oil temperature of 75 more or less 2°C [167 more or less 4°F].

9.3 When an automatic timer is used to terminate a test, it should be checked for the required 61 min accuracy at 60 min elapsed time.

9.4 The loading mechanism must be balanced to a zero reading with all parts and test oil in place. To demonstrate proper precision an addition or subtraction of 19.6 N [0.2 kgf] should be detectable in imbalance. Determination of accuracy of loading at 147 and 392 N [15 and 40 kgf] is difficult and generally limited to careful measurement of lever-arm ratios and weights or piston diameter and pressure gage calibration.