8. Cleanliness Procedure

8.1 Heat the sample in the original container in the heating bath or on a hot plate to above 90° to ensure the sample is in a fluid state.

8.2 Mix thoroughly.

NOTE 1 - Mechanical shaking or mechanical mixing is recommended.

8.3 Pour approximately 50 mL of the sample into a 100-mL conical flask and place the flask in the heating bath or on a hot plate.

8.4 Heat the sample uniformly by stirring and maintain the sample temperature between 90 and 95°C for 15 to 20 min.

8.5 Position the test paper so the test portion is clear of any support (Fig. 1) and place in the oven for a minimum of 5 min allowing the paper temperature to attain the oven temperature.

8.6 Preheat the glass rod by dipping into and stirring the heated sample for about 20 s. Withdraw the rod and allow the first drop to fall back into the conical flask. Allow the second drop to fall onto the test paper which is supported horizontally in the oven heated to a temperature of 100°C.

8.6.1 A number of samples may be spotted on the same test paper. The spot centers must not be closer than 50 mm and at least 25 mm from the edge of the test paper.

8.7 Dry the test paper in the oven maintained at 100 more or less 2°C for 1 h. The test paper must be kept level and supported in such a manner to prevent the spotted portion from coming into contact with any surface.

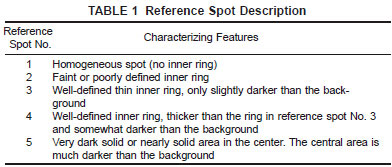

8.8 After 1 h, remove the test paper from the oven. Refer to the reference spot adjunct and to the reference spot descriptions given in Table 1. Compare the spot with the standard spots on the adjunct and record the spot number having the closest resemblance. If the sample spot is rated between two consecutive spots on the adjunct, record the larger number.

NOTE 2 - Ignore differences in overall darkness, color, size, and appearance of the outer edges.

9. Compatibility Procedure

9.1 Pour 30 mL of test sample in an appropriate container, heating if necessary.

9.2 Add an equal volume of blend stock to the test sample and mix the contents thoroughly.

9.3 The equal volume of blend is generally the most severe condition for measuring compatibility. If in actual practice an application requires a blending ratio other than equal parts, conduct the test using the actual blend ratio for the test results to have a good probability of being indicative of the final blend.

9.4 Immediately test 50 mL of the mixture as described in 8.3-8.8.