7. Apparatus

7.1 Gas Chromatograph, a temperature programmable gas chromatograph suitable for splitless injections; equipped with an ECD.

7.2 Data System, a data system capable of measuring peak areas.

7.3 Regulator (Make-up Gas) - N2 or Ar:Methane (95:5); two stage regulator rated at 20 MPa (3000 psi) inlet and 35 to 860 kPa (5 to 125 psi) outlet.

7.4 Regulator (Carrier Gas) - H2, two-stage regulator rated at 20 MPa (3000 psi) inlet and 35 to 860 kPa (5 to 125 psi) outlet.

7.5 Gas Purifiers, to remove moisture and particulates. Depending on the levels and types of interferences encountered, these might involve molecular sieves (moisture), activated carbon (organics), or other commercially-available media.

7.6 Flow Meter, to measure gas flow. Typical range is from 0.5 to 50 mL/min. (+/- 0.1 mL/min.)

7.7 Column, crosslinked 5 % phenyl methyl silicone, 30 m by 0.32 mm id by 0.25 um film thickness.

7.7.1 It is possible that other columns will provide sufficient separating power, but this shall be demonstrated before use.

7.8 Analytical Balance, capable of weighing to 0.0001 g.

7.9 Volumetric Flasks, 10, 50, 100, 200 mL, (see Specification E 288) Class A with ground-glass stoppers.

7.10 Vortex Mixer.

7.11 Vials, glass, 20 mL and 40 mL capacity with TFE-fluorocarbon-lined caps.

7.12 Septum Inserts - Inserts shall be treated with a silynization reagent before use or after cleaning. (See Annex A2 for possible procedure.) They may be purchased already treated.

7.13 Volumetric Pipette, 1, 5, 10 mL (see Specification E 969), Class A.

7.14 Syringe, 500 uL, mechanical guide.

8. Reagents and Materials

8.1 Purity of Reagents - Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all reagents conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society where such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity to permit its use without lessening the accuracy of the determination.

8.2 Acetone - See Note 3.

NOTE 3 - Warning: Extremely flammable. Vapors may cause flash fire.

8.3 Activated Magnesium Silicate (Florisil), Pesticide residue (PR) grade (60/100 mesh); store in glass containers with ground glass stoppers or foil lined screw caps.

8.3.1 Just before use, activate each batch at least 4 h at 130°C in a glass container loosely covered with aluminum foil. Alternatively, store the magnesium silicate in an oven at 130°C. Cool the magnesium silicate in a desiccator for 30 min before use.

8.4 Hexane - See Note 4.

NOTE 4 - Warning: Extremely flammable. Harmful if inhaled. May produce nerve cell damage. Vapors may cause flash fire.

8.5 Isooctane - See Note 5.

NOTE 5 - Warning: Extremely flammable. Harmful if inhaled. Vapors may cause flash fire.

8.6 Methanol - See Note 6.

NOTE 6 - Warning: Flammable. Vapor harmful. May be fatal or cause blindness if swallowed or inhaled. Cannot be made nonpoisonous.

8.7 Silynization Reagent (for example, 5 % dimethyldichlorosilane in toluene). See Annex A2 for instructions.

8.8 Sodium Sulfate, granular, anhydrous (maintained at 130°C for at least 24 h prior to use). Cool the sodium sulfate in a desiccator for 30 min before use.

8.9 Sulfuric Acid (concentrated):

8.10 Acetone/Hexane, 10 % acetone/90 % hexane (v/v).

8.11 Gases, Hydrogen (zero grade; 99.995 % purity) and nitrogen (zero grade; 99.998 % purity) or argon/methane (95:5; ECD grade).

8.11.1 Care shall be given to ensure purity of the carrier gas. For example, an in-line filter may be required.

8.12 Aroclor Standards3, Aroclor 1016, 1221, 1232, 1242, 1254, 1260, 1262, 1268.

8.13 Decachlorobiphenyl (DCB) (surrogate) Optional:

8.13.1 Surrogate Stock Standard (15 ug/mL) Preparation - Accurately dilute 1.5 mL of 1000 ug/mL DCB concentrate in 100 mL volumetric flask and fill to the mark with methanol, yielding a 15 ug/mL solution.

8.13.2 Surrogate Working Standard (1.5 ug/mL) Preparation - Accurately dilute 10 mL of the 15 ug/mL DCB stock standard in a 100 mL volumetric flask and fill to the mark with methanol, yielding a 1.5 ug/mL working DCB standard.

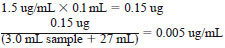

NOTE 7 - Sample preparations will normally use 0.1 mL of this solution. The resulting concentration in the sample extract is 0.005 ug/mL before any further dilutions. The following calculations show this.

8.14 Calibration Standards:

8.14.1 Intermediate Stock Standard (50 ug/mL):

If high level standards (for example, commercially available standards at 2000 to 5000 ug/mL) have been purchased, prepare solutions of 50 ug/mL concentration.

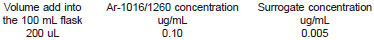

8.14.1.1 The surrogate calibration standard may be added (optional) to the Aroclor 1016/1260 intermediate stock standard at a concentration of 2.5 ug/mL. For preparation of the standard, add 500 uL of 50 ug/mL surrogate to a 10 mL volumetric flask containing 3.0 mL of isooctane. Add the Aroclor 1016/1260 standard (5.0 mL at 100 ug/mL) to the flask. Dilute to 10 mL volume with isooctane and mix well.

8.14.1.2 To prepare the continuing CCS, dilute 200 uL of the intermediate stock standard to 100 mL.

8.14.2 Instrument Performance Standard (IPS) (Tier I - Screening) - An isooctane solution of Aroclors 1016 and 1260 is prepared at a concentration of 0.01 ug/mL (each) or 0.1

ug/mL (each) (depending on whether the minimum level of interest is 2 ug/mL or 20 ug/mL) from the appropriate stock standard.

8.14.2.1 If the surrogate (decachlorobiphenyl, (DCB)) is used, it shall be added to the IPS to result in a concentration of 0.005 ug/mL.

8.14.2.2 To prepare the IPS along with DCB, add 10 mL of Aroclor 1016/1260 at 0.1 ug/mL and 0.033 mL of DCB at 15 ug/mL into 100 mL volumetric flask. Dilute to 100 mL volume with isooctane. Mix well. This yields 0.01 ug/mL IPS and 0.005 ug/mL of DCB.

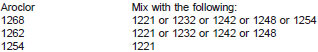

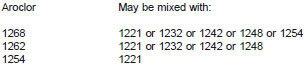

8.14.2.3 The following additional standards shall be run once (at 0.1 ug/mL) to demonstrate the Aroclor patterns and be mixed if preferred.

8.14.3 IndividualWorkingStandards(Tier 2 - Quantitation) - Working standards are typically prepared in isooctane at concentrations of 0.02 ug/mL, 0.05 ug/mL, 0.1 u/mL, 0.3 ug/mL and 0.5 ug/mL for Aroclors 1016 and 1260. All other Aroclors are prepared at the mid level concentration (0.1 ug/mL) for the single point calibration. An alternative calibration range may be used as long as the criteria for linearity of the calibration range is documented.

8.14.3.1 Aroclors 1016 and 1260 shall be a mixed standard. The following additional standards shall be run once (at 0.1 ug/mL) to demonstrate the Aroclor patterns and may be mixed, if preferred.

8.15 Quality Control Standards:

8.15.1 Calibration Check Standard (CCS) (Tier 2 - Quantitation) - This standard contains 0.1 ug/mL (those who are interested in the 20 mg/Kg level with no compositing, use 0.2 ug/mL each) each of Aroclors 1016 and 1260 in hexane.

8.15.1.1 The surrogate concentration, if used, is 0.005 ug/mL.

8.15.1.2 Example - To prepare the CCS along with DCB, add 20 mL of Aroclors 1016/1260 to 0.5 ug/mL and 0.05 mL of DCB at 10 ug/mL into 100 mL volumetric flask. Dilute to 100 mL volume with isooctane. Mix well. This yields a 0.1 ug/mL of CSS and 0.005 ug/mL of DCB.

8.15.2 Matrix Spiking Standard (Tier 2 - Quantitation) - The matrix spiking standard is to contain Aroclor 1268 at a concentration of 50 ug/mL in methanol. Laboratories working at lower calibration ranges will need to dilute this (for example, to 25 ug/mL).

8.16 Copper Powder, 200 mesh, 99 % min..

8.17 Silica Gel, 100 to 200 mesh.

9. Sampling

9.1 PCBs are hydrophobic compounds. Therefore, when sampling, all organic phases, including bottom sludge beneath aqueous phases, shall be sampled. Given the possible presence of alcohols and glycols, it is typically not acceptable to sample the organic phase only.

9.2 Headspace above stored standards and samples or extracts should be minimized such that the volume is less than 50 %.

9.3 Three mL of sample are required for each determination. No special sample preservation is required other than storage in a closed container with minimal headspace. It is accepted practice to use borosilicate glass containers with TFE-fluorocarbon-lined lids.