1. Scope

1.1 This test method was designed to evaluate an engine oil's resistance to aeration in automotive diesel engine service. It is commonly referred to as the Engine Oil Aeration Test (EOAT). The test is conducted using a specified 7.3L, direct-injection, turbocharged diesel engine on a dynamometer test stand. This test method was developed as a replacement for Test Method D892 after it was determined that this bench test did not correlate with oil aeration in actual service. The EOAT was first included in API Service Category CG-4 in 1995.

NOTE 1 - Companion test methods used to evaluate engine oil performance for specification requirements are discussed in the latest revision of Specification D4485.

1.2 The unit values stated in this test method shall be regarded as the standard. The values given in parentheses are provided for information only. SI units are considered the primary units for this test method. The only exception is where there is no direct SI equivalent, for example, screw threads, national pipe threads/diameters, and tubing size.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

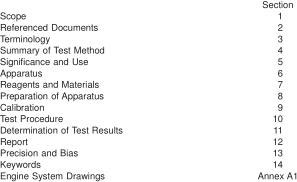

1.4 This test method is arranged as follows:

2. Referenced Documents

2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products

D93 Test Method for Flash Point by Pensky-Martens Closed Cup Tester

D97 Test Method for Pour Point of Petroleum Products

D130 Test Method for Detection of Copper Corrosion from Petroleum Products by the Copper Strip Tarnish Test

D287 Test Method for API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids

D482 Test Method for Ash from Petroleum Products

D524 Test Method for Ramsbottom Carbon Residue of Petroleum Products

D613 Test Method for Ignition Quality of Diesel Fuels by Cetane Method

D664 Test Method forAcid Number of Petroleum Products by Potentimetric Titration

D892 Test Method for Foaming Characteristics of Lubricating Oils

D1250 ASTM-IP Petroleum Measurement Tables

D1319 Test Method for Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator Absorption

D2500 Test Method for Cloud Point of Petroleum Products

D2622 Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry

D2709 Test Method for Water and Sediment in Middle Distillate Fuels by Centrifuge

D4052 Test Method for Density and Relative Density of Liquids by Digital Density Meter

D4175 Terminology Relating to Petroleum, Petroleum Products and Lubricants

D4485 Specification for Performance of Engine Oils

D4737 Test Method for Calculated Cetane Index by Four Variable Equation

D5844 Test Method for Evaluation of Automotive Engine Oils for Inhibition of Rusting

D5862 Test Method for Evaluation of Engine Oils in the Two-Stroke Cycle Turbocharged 6V92TA Diesel Engine

D6082 Test Method for High Temperature Foaming Characteristics of Lubricating Oils

D6557 Test Method for Evaluation of Rust Preventative Characteristics

D6594 Test Method for Evaluation of Corrosiveness of Diesel Engine Oil at 135°C

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

IEEE/ASTM SI 10 Standard for Use of the International System of Units (SI): The Modern Metric System

2.2 SAE Standard:

J 304 Engine Oil Tests

2.3 API Standard:

API 1509 Engine Oil Licensing and Certification System

3. Terminology

3.1 Definitions:

3.1.1 automotive, adj - descriptive of equipment associated with self-propelled machinery, usually vehicles driven by internal combustion engines.

3.1.2 calibrate, v - to determine the indication or output of a measuring device with respect to that of a standard.

3.1.3 candidate oil, n - an oil that is intended to have the performance characteristics necessary to satisfy a specification and is to be tested against that specification.

3.1.4 engine oil, n - a liquid that reduces friction or wear, or both, between the moving parts within an engine; removes heat particularly from the underside of pistons; and serves as combustion gas sealant for the piston rings.

3.1.4.1 Discussion - It may contain additives to enhance certain properties. Inhibition of engine rusting, deposit formation, valve train wear, oil oxidation, and foaming are examples.

3.1.5 foam, n - in liquids, a collection of bubbles formed in or on the surface of a liquid in which the air or gas is the major component on a volumetric basis.

3.1.6 heavy-duty, adj - in internal combustion engine operation, characterized by average speeds, power output and internal temperatures that are close to the potential maximums.

3.1.7 heavy-duty engine, n - in internal combustion engines, one that is designed to allow operation continuously at or close to its peak output.

3.1.8 lubricant, n - any material interposed between two surfaces that reduces the friction or wear, or both, between them.

3.1.9 non-reference oil, n - any oil other than a reference oil; such as a research formulation, commercial oil, or candidate oil.

3.1.10 reference oil, n - an oil of known performance characteristics, used as a basis for comparison.

3.1.11 test oil, n - any oil subjected to evaluation in an established procedure.

3.1.12 used oil, n - any oil that has been in a piece of equipment (for example, an engine, gearbox, transformer, or turbine), whether operated or not.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 aeration, n - in liquids, the action of impregnating with air that forms foam bubbles in or on the surface of a liquid or is entrained as a dispersion in that liquid.

3.2.2 flush, n - the action of cleaning out the engine oil system using new test oil to remove any residues as well as to minimize possible carryover effect from the previous test oil.

3.2.3 HEUI, n - hydraulically-actuated, electronically-controlled, unit injector.