12. Procedure

12.1 Analyze the blends (9.2.3) according to the following test sequence.

12.1.1 Two coarse determinations using Blends A1 and B1.

12.1.1.1 The coarse determinations are used to estimate suitable starting values of FR for the fine determinations. The coarse determinations may be skipped when the operator has a good approximation of the sample's Po and FRmax parameters.

NOTE 7 - During the coarse determination, cetane is added to decrease FR by 5 % stepwise.

NOTE 8 - Appendix X3 shows an example of coarse dilution steps with cetane for Blend A1.

12.1.2 Four fine determinations using Blends A2, B2, C, and D.

NOTE 9 - During the fine determination, cetane is added to decrease FR by 1 % stepwise.

NOTE 10 - Appendix X3 shows an example of fine dilution steps with cetane for Blend A2.

12.2 Initiate an automatic test sequence on the computer according to the manufacturer's instruction manual.

12.3 Test Procedure:

12.3.1 Place the reaction cell into the appropriate heater position. Place the reaction cells from left (Heater 1) to right (Heater 2). The left position always contains the blend with the letter that is alphabetically first; that is, A before B before C before D. Single blend determinations must always be in left (1) position.

12.3.2 Position the clean optical probe in the reaction cell. Allow the blend to warm up, until its viscosity is low enough to obtain a smooth stirring performance.

12.3.3 Place the dosing tube of the titration apparatus into the reaction cell. Make sure that the end of the tube does not touch the glass sleeve of the optical probe inside the cell to prevent titrant running down the glass sleeve. The position of the tube is such that droplets fall directly into the sample vortex so that mixing is optimal.

12.3.4 Switch on the magnetic stirrer and adjust the speed so that agitation is just visible on the surface of the sample. Higher viscosity samples may require a higher speed.

12.3.5 Initiate the automatic test procedure according to the manufacturer's instruction manual.

NOTE 11 - See Appendix X4 for detailed automatic test program.

13. Calculation of Results

13.1 The following calculations can be completed manually, but they are also performed automatically by the computer system.

13.2 Calculate the flocculation ratio at the critical dilution and the reciprocal critical dilution for the Blends A2, B2, C, and D.

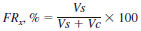

13.2.1 Calculation of flocculation ratio at critical dilution, FRx:

where:

Vs = millilitres of 1-methylnaphthalene (9.2.3.2), and

Vc = millilitres of cetane at inflection point as measured in 12.3.

13.2.2 Calculation of reciprocal critical dilution, 1/Xc:

where:

Vs = millilitres of 1-methylnaphthalene (9.2.3.2),

Vc = millilitres of cetane at inflection point as measured in 12.3, and

Ma = grams of sample (9.2.3.1).

13.3 Plot the flocculation ratio at critical dilution values against the reciprocal critical dilution values for each of the four blends. Draw a straight line through the four points using the quadratic least-squares fit equation. Extrapolate the line to the x- and y-axes to determine the reciprocal critical cetane dilution (1/Xmin) and the maximum flocculation ratio (FRmax). The value of 1/Xmin is the point at which the line intercepts the x-axis, the y intercept is FRmax (see Fig. 2).

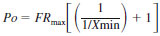

13.4 Calculate the peptizing power using Eq 3: