8. Procedure

8.1 Raise the temperature of the oven to the desired level and make certain that it remains constant within more or less 2°C for at least 30 min. The temperature of the cold trap will depend on the coolant employed. (The temperature of liquid air, or liquid nitrogen, is -195°C and of carbon dioxide snow is -78°C.)

8.2 Evacuate the degassing chamber with stopcock B closed and stopcock C open.

8.3 When the McLeod gage is reasonably constant and less than 0.1 mm Hg (absolute pressure), close stopcock C for about 15 min to test for any leaks. No observable pressure change should occur in this time. (Let the vacuum pump run continuously to enhance the seal of stopcock C.)

8.4 Flush oil slowly from the sample through stopcocks B and C so as to wash thoroughly the walls of the glass tubing and to remove any trapped air bubbles in the system above stopcock B. (About 50 mL of oil are commonly used for this flushing.)

8.5 Re-evacuate the degassing chamber, close stopcock C, read the McLeod gage and record as P1, then by careful manipulation of stopcock B feed oil from the sample container into the degassing chamber at a very slow rate so that the oil falls in single drops from pipet D. This rate will generally average 1 drop/s or less. A fritted disk, if employed, requires no regulation as it is self-monitoring. In the case of any significant positive pressure, a suitable means of reducing the pressure should be employed so as to allow the fritted disk to be self-monitoring. The oil should show no appreciable tendency to bubble or foam after falling into the oil well at the bottom of the degassing chamber. If this occurs the rate of flow should be decreased.

8.6 When 50 mL of oil (Note 4) have been degassed, close stopcock B and read the pressure, P2, on the McLeod gage. Record P2, room temperature, ta, oven temperature, td, and cold trap temperature, tt.

NOTE 4 - Smaller sample volumes than 50 mL may be desirable when measuring insulating liquids having high gas content.

8.7 Remove the sample container from the apparatus with stopcock B closed. Discharge the sample from the oil well by opening stopcock C. Vent the apparatus to atmosphere by careful manipulation of stopcock B.

9. Calculation

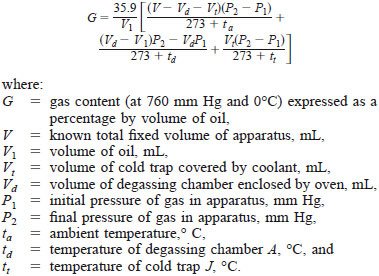

9.1 Calculate the gas content as follows:

NOTE 5 - The calculation may appear to be tedious, but when the fixed volumes and temperatures are substituted in the equation, it will be found that it can be simplified considerably. Simplification will also be aided if P1 can be made low enough to be negligible.