(Equivalent Test Methods: IP 267, ISO 9262, and AFNOR T42-011)

GENERAL

Many petroleum products are used as lubricants for bearings, gears, compressor cylinders, hydraulic equipment, etc. The proper operation of the equipment depends upon the proper kinematic viscosity or viscosity (sometimes called dynamic viscosity) of the liquid. Thus, the accurate measurement of kinematic viscosity and viscosity is essential to many product specifications.

The kinematic viscosity of many petroleum fuels is important for their proper use, for example, flow of fuels through pipe lines, injection nozzles and orifices, and the determination of the temperature range for proper operation of the fuel in burners.

EXPLANATION

The low-temperature, low-shear-rate viscosity of gear oils, automatic transmission fluids, torque and tractor fluids, and industrial and automotive hydraulic oils are frequently specified by Brookfield viscosities. This test method describes the use of the Brookfield viscometer for the determination of the low-shear-rate viscosity of automotive fluid lubricants in the temperature range from -5 to -40° C. The viscosity range is 500 to 1 000 000 cP mPa•s . Brookfield viscosity is expressed in centipoises (1 cP = 1 mPa•s). Its value may vary with the spindle speed (shear rate) of the Brookfield viscometer because many automotive fluid lubricants are non-Newtonian at low temperatures.

TEST SUMMARY

A lubricant fluid sample is cooled in an air bath at test temperature for 16 h. It is carried in an insulated container to a nearby Brookfield viscometer where its Brookfield viscosity is measured at any test temperature in the range from -5 to -40° C.

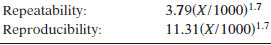

TEST PRECISION

Where X is the mean result.