IEC 60599 Mineral oil-impregnated electrical equipment in service - Guide to the interpretation of dissolved and free gases analysis

1 Scope

This International Standard is a guide describing how the concentrations of dissolved gases or free gases may be interpreted to diagnose the condition of oil-filled electrical equipment in service and suggest future action.

This guide is applicable to electrical equipment filled with mineral insulating oil and insulated with cellulosic paper or pressboard-based solid insulation. Information about specific types of equipment such as transformers (power, instrument, industrial, railways, distribution), reactors, bushings, switchgear and oil-filled cables is given only as an indication in the application notes (see annex A).

The Guide may be applied only with caution to other liquid-solid insulating systems.

In any case, the indications obtained should be viewed only as guidance and any resulting action should be undertaken only with proper engineering judgment.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this International Standard. At the time of publication, the editions indicated were valid. All normative documents are subject to revision, and parties to agreements based on this International Standard are encouraged to investigate the possibility of applying the most recent editions of the normative documents indicated below. Members of IEC and ISO maintain registers of currently valid International Standards.

IEC 60050(191):1990, International Electrotechnical Vocabulary (IEV) - Chapter 191: Dependability and quality of service

IEC 60050(212):1990, International Electrotechnical Vocabulary (IEV) - Chapter 212: Insulating solids, liquids and gases

IEC 60050(604):1987, International Electrotechnical Vocabulary (IEV) - Chapter 604: Generation, transmission and distribution of electricity - Operation

IEC 60567:1992, Guide for the sampling of gases and of oil from oil-filled electrical equipment and for the analysis of free and dissolved gases

IEC 61198:1993, Mineral insulating oils - Methods for the determination of 2-furfural and related compounds

3 Definitions and abbreviations

3.1 Definitions

For the purpose of this International Standard, the following definitions, some of them based on IEC 60050(191), IEC 60050(212) and IEC 60050(604) apply:

3.1.1 fault

an unplanned occurrence or defect in an item which may result in one or more failures of the item itself or of other associated equipment [IEV 604-02-01]

NOTE In electrical equipment, a fault may or may not result in damage to the insulation and failure of the equipment.

3.1.2 non-damage fault

a fault which does not involve repair or replacement action at the point of the fault [IEV 604-02-09]

NOTE Typical examples are self-extinguishing arcs in switching equipment or general overheating without paper carbonization.

3.1.3 damage fault

a fault which involves repair or replacement action at the point of the fault [IEV 604-02-08, modified]

3.1.4 incident

an event related to an internal fault which temporarily or permanently disturbs the normal operation of an equipment [IEV 604-02-03, modified]

NOTE Typical examples are gas alarms, equipment tripping or equipment leakage.

3.1.5 failure

the termination of the ability of an item to perform a required function [IEV 191-04-01]

NOTE In the electrical equipment, failure will result from a damage fault or incident necessitating outage, repair or replacement of the equipment, such as internal breakdown, rupture of tank, fire or explosion.

3.1.6 electrical fault

a partial or disruptive discharge through the insulation

3.1.7 partial discharge

a discharge which only partially bridges the insulation between conductors. It may occur inside the insulation or adjacent to a conductor [IEV 212-01-34, modified]

NOTE 1 Corona is a form of partial discharge that occurs in gazeous media around conductors which are remote from solid or liquid insulation. This term is not to be used as a general term for all forms of partial discharges.

NOTE 2 X-wax is a solid material which is formed from mineral insulating oil as a result of electrical discharges and which consists of polymerized fragments of the molecules of the original liquid [IEV 212-07-24, modified]. Comparable products may be formed from other liquids under similar conditions.

NOTE 3 Sparking of low energy, for example because of metals or floating potentials, is sometimes described as partial discharge but should rather be considered as a discharge of low energy.

3.1.8 discharge (disruptive)

the passage of an arc following the breakdown of the insulation [IEV 604-03-38, modified]

NOTE 1 Discharges are often described as arcing, breakdown or short circuits. The more specific following terms are also used:

- sparkover (discharge through the oil);

- puncture (discharge through the solid insulation);

- flashover (discharge at the surface of the solid insulation);

- tracking (the progressive degradation of the surface of solid insulation by local discharges to form conducting or partially conducting paths);

- sparking discharges which, in the conventions of physics, are local dielectric breakdowns of high ionization density or small arcs.

NOTE 2 Depending on the amount of energy contained in the discharge, it will be described as a discharge of low or high energy, based on the extent of damage observed on the equipment (see 5.2).

3.1.9 thermal fault

excessive temperature rise in the insulation

NOTE Typical causes are

- insufficient cooling,

- excessive currents circulating in adjacent metal parts (as a result of bad contacts, eddy currents, stray losses or leakage flux),

- excessive currents circulating through the insulation (as a result of high dielectric losses), leading to a thermal runaway,

- overheating of internal winding or bushing connection lead.

3.1.10 typical values of gas concentrations

gas concentrations normally found in the equipment in service which have no symptoms of failure, and which are overpassed by only an arbitary percentage of higher gas contents, for example 10 % (see 8.2.1)

NOTE 1 Typical values will differ in different types of equipment and in different networks, depending on operating practices (load levels, climate, etc.).

NOTE 2 Typical values, in many countries and by many users, are quoted as "normal values", but this term has not been used here to avoid possible misinterpretations.

3.2 Abbreviations

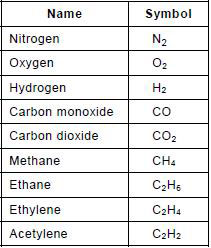

3.2.1 Chemical names and symbols

3.2.2 General abbreviations

DGA: Dissolved gas analysis

CIGRE: Conférence Internationale des Grands Réseaux Électriques

S: Analytical detection limit