Have you ever been reading a laboratory report listing the results from testing of a transformer oil sample and wondered what the results are trying to tell you? Words like sludge or metallic soaps, x-wax or ionic species creep into the vernacular and leave you scratching your head and wondering what significance that terminology really is. I am sure you are not alone in this regard.

This article will discuss one of these terms, sludge. It will also briefly discuss sludge formation in transformers, what it is, and its significance. Three basic analytical tests are useful detectors of the precursors to sludge formation and precipitation.

Interfacial Tension (ASTM D971, mN/m): The interfacial tension of an oil is the force in dynes per centimeter (milliNewtons per meter) required to rupture the oil film existing at an oil-water interface. When certain contaminants such as soaps, paints, varnishes, and oxidation by-products are present in the oil, the film strength of the oil is weakened, thus requiring less force to rupture. For oils in service, a decreasing value of interfacial tension indicates the accumulation of contaminants, oxidation by-products, or both. This reduction is a precursor of objectionable oxidation by-products that may attack the insulation and interfere with the cooling of transformer windings.

Neutralization Number (ASTM D974, mgKOH/g): The neutralization number of an oil is a measure of the amount of acidic or alkaline materials present. It is a simple acid/base titration and some use it interchangeably with acid content. As oils age in service, the acidity and therefore the neutralization number increases. Used oil having a high neutralization number indicates that the oil is either oxidized or contaminated with materials such as varnish, paint, or other foreign matter. (A basic neutralization number results from an alkaline contaminant in the oil).

Pentane-Insoluble Sludge: This test is a qualitative test in which insoluble sludge is found to be either present or absent based on a visual inspection. The test is conducted by mixing oil from the sample and a defined amount of a hydrocarbon solvent, pentane. The mixture is held for 16-24 hours in a cool, dark place and then examined by tilting the vial and visually inspecting for tiny solid particles of gelatinous clumps. This solid material forms from soluble sludge which precipitates due to the addition of the hydrocarbon solvent.

These tests are important as they are good indicators of the formation of degradation by-products of both oil and paper that are oil soluble. The value for the interfacial tension decreases and the neutralization number increases in response to the formation of organic acids and polar compounds (compounds with an oxygen-bonded atom), both of which are detrimental to the quality of the oil. These by-products will eventually lead to sludge formation which should be avoided. The pentane-insoluble sludge test is a quick test that Doble uses to detect the early stages of sludge formation.

The development of sludge in a transformer is deleterious and presents a number of problems. Once formed in the oil, it can layer on the winding insulation and in the oil ducts. In these cases it acts as a thermal insulator. That is, it prevents the transformer from being cooled properly, and thus more overheating occurs which contributes to even more sludge formation so it is a continuously compounding problem. The additional heat reduces the life of both the oil and paper insulation but mainly the paper insulation. Sludge may be slightly conductive as well, depending on its composition, reducing the dielectric strength of the solid/liquid insulation. Because it is a polar type material it has a tendency to attract water which increases its conductivity.

The formation of sludge presents maintenance issues as well. Oils with a low interfacial tension and an elevated neutralization number are easy to reclaim by removing the precursors of sludge through the use of activated clay (Fuller's earth) or activated aluminum. However, once sludge precipitates as a solid and bakes on the insulation or mechanical structures of the transformer, much more effort, time, and money are needed to remove it. The primary reason is that it tends to attach to the windings and other surfaces so it is not readily dissolved in oil and thus not easy to remove.

How does Sludge Form and What is it? Sludge forms from the degradation of the oil and paper insulation due to stressors such as oxygen and temperature and catalysts such as copper. The early precursors of sludge are peroxides, organic acids, alcohols, aldehydes, ketones, lacquers, and other aromatic compounds, particularly those that have polar functional groups. As these materials attack other transformer components such as the paper, iron, and copper, they form intermediate by-products in the oil that then polymerize together to form a solid type material which is called sludge. This is the terminal stage of this degradation process. Sludge tends to precipitate out in the coldest and hottest regions of the transformer.

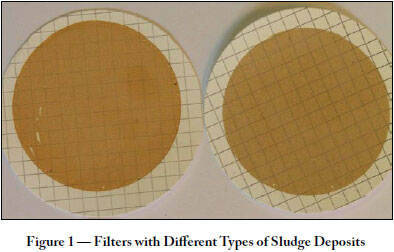

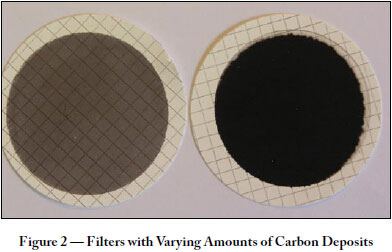

Sludge and Carbon: Carbon fines and sludge fines are often confused with each other. Sludge is formed as a result of the process already described. Carbon is formed from a totally separate process in which the carbon atoms are completely separated from the hydrocarbon molecules found in transformer oil. The process also generates hydrogen and hydrocarbon gases and requires a large amount of energy such as that resulting from very high temperature overheating or discharge conditions. Carbon is present in transformers but most often present in load tap-changers and oil circuit breakers as arcing occurs more frequently in these devices. Once either sludge or carbon is filtered from the oil it is usually very easy to distinguish between the two. Carbon is usually very black or gray depending on how much carbon is present. Sludge can form various colors including tan, tannish-green, brown, beige, etc., but not black. See Figures 1 and 2.