EXPLANATION

When an engine oil is cooled, the rate and duration of cooling can affect its yield stress and viscosity. In this laboratory test an engine oil is slowly cooled through a temperature range where wax crystallization is known to occur, followed by relatively rapid cooling to the final test temperature. These laboratory test results have predicted as failures the known engine oils that have failed in the field due to the lack of oil pumpability. These documented field failing oils have all consisted of oils normally tested at -25° C. These field failures are believed to be the result of the oil forming a gel structure that results in excessive yield stress or viscosity of the engine oil, or both.

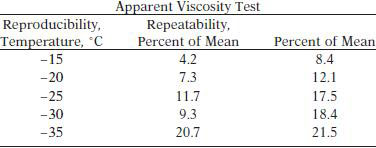

This test method covers the measurement of the yield stress and viscosity of engine oils after cooling at controlled rates over a period exceeding 45 h to a final test temperature between -15 and -30° C. The applicability to petroleum products other than engine oils has not been determined.

TEST SUMMARY

An engine oil sample is held at 80° C and then cooled at a programmed cooling rate to a final test temperature. A low torque is applied to the rotor shaft to measure the yield stress. A higher torque is then applied to determine the apparent viscosity of the sample.

TEST PRECISION

Since yield stress is a pass-fail test, no precision data are available.