EXPLANATION

Wax treatment is used to improve resistance to moisture damage of corrugated fiberboard shipping containers. This commonly involves a light wax saturation applied to the medium and facings, followed by a curtain coating or roll coating operation applying wax to the surface. This test method measures weight of wax that has been applied and the amount of impregnating wax in the same facing. The method assumes that the major portion of the molten coating applied will congeal and remain on the surface without undue migration into the fibrous structure of the medium. This test method is especially applicable to board that has a coated surface and also contains wax saturation within the facing structure.

The amount of surface wax on board that may or may not contain impregnating wax within its structure may be determined alternatively by Test Method D3521. If it is known that the specimen has coating wax only, with no internal impregnating wax, the total coating wax applied may be determined by Test Method D3344.

TEST SUMMARY

The coated facing is peeled from the medium and then split into two layers, one bearing the coating on waxed fibers and one containing the waxed fibers only. The layers are extracted separately, collecting both fibers and wax, leading to a calculation of the applied surface coating wax and the amount of impregnating wax.

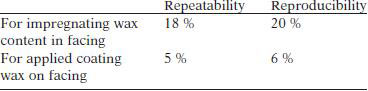

TEST PRECISION

This method has no bias because the value can be defined only in terms of a test method.