ASTM D1796 standard test method for water and sediment in fuel oils by the centrifuge method (Laboratory Procedure)

8. Procedure

8.1 Fill each of two centrifuge tubes to the 50-mL mark with the well-mixed sample directly from the sample container. Then, using a pipette, add 50 mL of the water-saturated solvent. Read the top of the meniscus at both the 50 and 100-mL marks. Stopper the tubes tightly and shake vigorously until the contents are thoroughly mixed. Loosen the stoppers on the tubes and immerse the tubes to the 100-mL mark for 10 min in the bath maintained at 60 more or less 1°C (140 more or less 2°F).

8.2 Tighten the stoppers and again invert the tubes to ensure that the oil and solvent are uniformly mixed and shake cautiously. (Warning - In general, the vapor pressures of hydrocarbons at 60°C (140°F) are approximately double those at 40°C (104°F). Consequently, tubes should always be inverted at a position below eye level so that contact will be avoided if the stopper is blown out.)

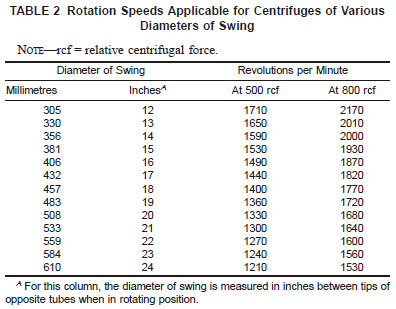

8.2.1 Place the tubes in the trunnion cups on opposite sides of the centrifuge to establish a balanced condition, and spin for 10 min at a rate, calculated from the equation given in 5.1, sufficient to produce a relative centrifugal force (rcf ) of between 500 and 800 at the tip of the whirling tubes (see Table 2 for the relationship between diameter of swing, relative centrifugal force, and revolutions per minute). The temperature of the sample during the entire centrifuging procedure shall be maintained at 60 more or less 1°C (140 more or less 2°F). (See Note 2.)

8.2.2 Immediately after the centrifuge comes to rest following the spin, read and record the combined volume of water and sediment at the bottom of each tube to the nearest 0.05 mL from 0.1 to 1-mL graduations and to the nearest 0.1 mL above the 1-mL graduations. Below 0.1 mL estimate to the nearest 0.025 mL (see Fig. 2). If less than 0.025 mL of water and sediment is visible and it is not a great enough volume to be considered 0.025 mL, record the volume as less than 0.025 mL. If no water or sediment is visible, record the volume as 0.000 mL. Return the tubes without agitation to the centrifuge and spin for another 10 min. at the same rate.

8.2.3 Repeat this operation until the combined volume of water and sediment remains constant for two consecutive readings. In general, not more than two spinnings are required.

8.2.4 If the difference between the final volumes is not greater than one subdivision on the centrifuge tube (see Table 1), or, for estimated volumes of 0.10 mL or lower, proceed with the calculation of water and sediment content using Eq 3 as described in Section 9. If the difference is greater than one subdivision or, for readings of 0.10 or below, greater than 0.025 mL, the readings are inadmissible and the determination shall be repeated starting at 8.1.

9. Calculation

9.1 Record the final volume of water and sediment in each tube and report the sum of these two readings as the percentage of sediment and water. Report results lower than 0.05 % either as 0 or 0.05, whichever is closer.

9.2 Calculate the water and sediment of the sample as follows:

V = V1 + V2

where:

V = water and sediment of the sample (the test result, % V/V,

V1 = final volume of water and sediment per 50 mL of sample in the first tube, mL, and

V2 = final volume of water and sediment per 50 mL of sample in the second tube, mL.

9.3 Express the sum of the two admissible readings as the percentage by volume of water and sediment.