5. Apparatus

5.1 Flask - Distillation flask, 300 mL, specified as Type II, Class 2 in Specification E 1405.

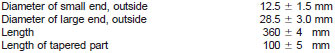

5.2 Condenser Tube - A tapered glass condenser, as shown in Fig. 1 and Fig. 2, conforming to the following dimensions:

5.3 Source of Heat - A source of heat consisting of a bunsen or Meker type gas burner or an electric heater. The electric heater shall have an output variable to 600 or to 750 W and removable upper and lower refractories as illustrated in Fig. 3. The temperature of the heater shall be controlled by a variable transformer or rheostate suitable for the voltage used, and shall be fitted with a clamp for mounting on a vertical support rod.

5.4 Flask Shield for Flame Distillation - A stainless steel shield, fitted with mica windows and lined with 1/8-in. heat-resistant ceramic board, with two-part cover made from 1/4-in. "Transite" board of the forms and dimensions shown in Fig. 4.

5.5 Flask Shield for Electric-Heater Distillation - A stainless steel shield fitted with mica windows and cover of the same construction and dimensions as those for flame distillation (5.4), except for the height of the shield.

5.6 Gauze - Two sheets of 16-mesh wire gauze made with 0.51-mm (0.02-in.) diameter Nichrome wire and 125 to 152 mm in diameter or square.

5.7 Burner Chimney for Flame Distillation - A cylindrical metal chimney approximately 100 mm high, 95 to 105 mm in diameter, and having a peephole 25 mm in diameter centered about 32 mm below the ring support, used to protect the flame from air currents. The top of the shield should be flanged to permit its being suspended from the ring support.

5.8 Receivers - Standard 125-mL conical flasks, specified as Type I, Class 1 in Specification E 1404.

5.9 Balance and Weights, accurate to 0.05 g.

5.10 Thermometer - An ASTM high-distillation thermometer having a range from -2 to +400°C and conforming to the requirements for Thermometer 8C as prescribed in Specification E 1.