11. Procedure

11.1 To a dry, 100-mL graduated, glass-stoppered cylinder, add 15 mL of xylene and pipet (total delivery) in 10 mL of the crude oil sample. Rinse the pipet with xylene until free of oil. Make up to 50 mL with xylene. Stopper and shake the cylinder vigorously for approximately 60 s. Dilute to 100 mL with mixed alcohol solvent, and again shake vigorously for approximately 30 s. After allowing the solution to stand for approximately 5 min, pour it into the dry test beaker.

11.2 Follow the procedure in 10.4 to obtain voltage and current readings. Record the indicated electrode current to the nearest 0.01 mA and the nearest voltage.

11.3 Remove the electrodes from the sample solution, and clean the apparatus.

12. Calculation

12.1 Subtract the value obtained for the blank measurement from the value obtained from the specimen measurement to obtain the net current reading. From the calibration graph, read the indicated salt concentration corresponding to the net current (mA) reading of the sample.

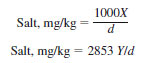

12.2 Calculate the concentration in mg/kg by using the appropriate equation given below:

where:

X = measured salt concentration in g/m3,

Y = measured salt concentration in PTB, and

d = specimen density at 15 C in kg/m3.

NOTE 9 - The density of the specimen can be determined by various methods, such as Test Method D5002 or other density measurement methods.

13. Report

13.1 Report the following information: The concentration in mg/kg as electrometric chloride in crude oil per Test Method D3230. Alternately, report the concentration directly in g/m3 or lb/1000 bbl, if so required.

NOTE 10 - For reporting purposes, the values stated in PTB are the preferred units in the United States; in other countries, their common units can be used.

14. Precision and Bias

14.1 Precision - The precision of this test method as determined by the statistical examination of the 1997 interlaboratory test results is as follows:

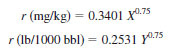

14.1.1 Repeatability - The difference between successive results, obtained by the same operator with the same apparatus under constant operating conditions on identical test material, would in the long run, in the normal and correct operation of the test method, exceed the following values in one case in twenty.

where:

X = the average of two test results in mg/kg, and

Y = the average of two test results in lb/1000 bbl (PTB).

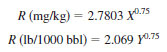

14.1.2 Reproducibility - The difference between two single and independent results, obtained by different operators working in different laboratories on identical material, would in the long run, exceed the following values in only one case in twenty.

where:

X = the average of two test results in mg/kg, and

Y = the average of two test results in lb/1000 bbl (PTB).

NOTE 11 - Since all instruments in the 1997 interlaboratory cooperative test program were calibrated in PTB and results reported in PTB, the precision statement was directly obtained in PTB. The resulting precision data have been mathematically converted into precision in mg/kg, assuming an average density of the crude oil samples of 0.875 kg/L.

14.2 Bias - The procedure in Test Method D3230 has no bias since salt content is defined only in terms of this test method and certified reference materials are unavailable. However, since the samples from the interlaboratory study were neat desalted crudes, spiked with known quantities of salt (as sea water and formation water), bias might be defined as percent recovery of halide added. Over the range from 5 to 500 g/m3(1.5 to 150 PTB) salt added, the recovery proved to be approximately constant and averaged 93 %.

14.3 The precision statements were derived from a 1997 interlaboratory cooperative test program. Participants analyzed eight sample sets comprised of crude oils with various concentrations of chlorides. Thirteen laboratories participated with the commercial available apparatus.

15. Keywords

15.1 chlorides; crude oil; electrometric; halides; petroleum; salt in crude