TEST METHOD C - ETHYLBENZENE AND TOTAL AROMATICS CONTENTS BY MEANS OF A SINGLE CAPILLARY COLUMN GAS CHROMATOGRAPHIC ANALYSIS

18. Apparatus

18.1 Gas Chromatograph - Any gas chromatograph equipped with a split/splitless capillary injector and flame ionization detector capable of operating at the conditions listed in Table 3 may be employed.

18.2 Sample Introduction - Manual or automatic liquid syringe sample injection may be employed. Devices capable of delivering between 0.1 to 1 µL are suitable.

18.3 Sensitivity - The overall sensitivity of the detector shall be sufficient to detect 0.1 volume % of any aromatic compound of interest with a peak height of at least 5 times the height of the noise level.

18.4 Column - A 60 m x 0.25 mm inside diameter by 0.4-µm film thickness, fused silica capillary column coated with triscyanoethoxypropane (TCEP) has been found to be acceptable. Calculate the resolution in accordance with 5.1.2.2. The resolution, R, shall be no less than 2.0. Other columns may be used provided they meet the specified performance criteria.

18.4.1 Ethyl benzene shall be separated from p-xylene with a depth of the valley after ethyl benzene not less than 75 % of the ethyl benzene peak height. P-xylene shall be separated from cumene with the depth of the valley after p-xylene not less than 75 % of the p-xylene peak height.

NOTE 9 - TCEP is a low temperature, nonbonded stationary phase. It was observed during the interlaboratory study that with continued use, significant loss of stationary phase occurred resulting in progressively shorter retention times for all peaks. As a result, this affected proper peak identification and area integration when using automated electronic data processing. Due to the observed changes in retention times with time, it is recommended that the calibration blend be run prior to any analysis. If the retention time for toluene has shifted by more than 0.1 min, recalibrate the method to reflect the shift in retention times. To achieve the maximum useful lifetime of the column, it is suggested that the oven temperature be lowered to 50°C when the column is not in use.

18.5 Data Acquisition:

18.5.1 Recorder - A recording potentiometer or equivalent with a full-scale deflection of 5 mv or less may be used. Full-scale response time should be 1 s or less to accommodate peaks eluting from a capillary column.

18.5.2 Electronic Integration - Any electronic data acquisition system or integration device, or both, suitable for capillary gas chromatography may be used.

18.6 Chromatographic Conditions - The chromatographic conditions that have been found to be particularly suitable for this test method are listed in Table 3.

19. Reagents and Materials (See Section 6)

20. Preparation of Apparatus

20.1 Install and condition the capillary column according to the instrument and column manufacturer's recommendations.

20.2 After conditioning the column, adjust the carrier gas head pressure such that an average linear velocity of 20 cm/s, measured using methane, is obtained at a column temperature of 110°C.

20.2.1 The average linear gas velocity is calculated as follows:

u = L/tm

where:

u = average linear gas velocity,

L = the length of the column in cm, and

tm = is the retention time of methane in seconds.

20.3 After setting the specified average linear gas velocity, adjust the remaining GC parameters to conform to those listed in Table 3.

21. Calibration

21.1 Preparation of Test Blend - Prepare a test blend as described in 7.1.

21.2 Inject the test blend into the column using the conditions specified in Table 3. Change the attenuation, if necessary, so that the internal standard and aromatic peaks are measured with a chart deflection of not more than 25 % nor more than 95 % of full scale for attenuated peaks. Check the column performance against the requirements given in 5.1.2.

21.3 A typical chromatogram of the test blend analyzed under the conditions listed in Table 3 is shown in Fig. 3.

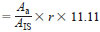

21.4 Response Factor - Assume that the aromatics in the sample have the same relative response as pseudocumene in the test blend. Using the results from the test blend, calculate the response factor as follows:

where:

r = relative response factor for aromatics,

AIS = area of the internal standard peak in arbitrary units,

VIS = volume % of the internal standard in the blend,

Aa = area of the pseudocumene peak in arbitrary units, and

Va = volume % of pseudocumene in the blend.

22. Procedure (See Section 8)

22.1 Using the exact instrument conditions as were used for calibration, inject the test material. Inspect the chromatogram to determine that there is complete resolution between saturated and aromatic peaks.

22.2 Pipet exactly 1.0 mL of cyclohexanone internal standard into a 10-mL volumetric flask. Fill to the mark with the sample, cap, and mix by inverting several times.

22.3 Using the exact instrument conditions as were used for calibration, inject the same volume of sample containing the internal standard. Change the attenuation, if necessary, so as to measure the area of the internal standard and aromatic peaks with not less than 25 % nor more than 95 % chart deflection on attenuated peaks.

23. Calculation

23.1 Measure the areas of all aromatic and internal standard peaks. Use of an electronic integrator is recommended to obtain the best accuracy and precision.

NOTE 10 - Aromatic peaks are assumed to be all peaks, excluding the internal standard, eluting after nC13 in the chromatogram. C8 plus heavier aromatics are all peaks, excluding the internal standard, that elute after toluene. Because the C8 plus heavier aromatic compounds may not be completely resolved from each other, peak height multiplied by one half width or retention time must not be used as a means of measuring them. A sum of the peak areas measured by electronic integration is recommended.

23.2 If a different attenuation is used for part of the chromatogram (strip chart recorder using manual integration techniques), correct to a constant attenuation basis by multiplying the area of the aromatic peaks by the ratio:

Sa/Ss

where:

Ss = attenuation sensitivity used for the internal standard peak, and

Sa = attenuation sensitivity used for the aromatic peak area.

23.3 Calculate the concentrations of ethylbenzene and C8 plus heavier aromatics as follows:

Va = (Aa x r x 10)/(AIS x 0.9)

where:

Va = volume % of aromatic compound(s),

Aa = area of the aromatic peaks (individual, in the case of ethylbenzene, or summed, in the case of C8 plus heavier aromatics) corrected to a constant attenuation,

r = relative response factor for the aromatic compounds,

10 = volume % of the internal standard,

AIS = area of the internal standard peak, and

0.9 = factor to correct for the dilution by the internal standard.

23.4 Total Aromatics - Add the amounts of the aromatic compounds found to obtain the volume percent of total aromatics in the sample.

24. Report

24.1 Report the following information: Concentration of ethylbenzene, total aromatics and C8 plus heavier aromatics (except ethylbenzene) in volume percent to the nearest 0.1 %.

25. Precision and Bias

25.1 Precision - The following criteria should be used to judge the acceptability (95 % probability level) of results obtained by this test method. The criteria were derived from a interlaboratory study among 9 laboratories utilizing a total of 8 samples, 5 of them were actual mineral spirits and three were synthetic blends used to determine bias, ranging in total aromatics content from <1 to 17 vol %. The interlaboratory study was conducted and results analyzed in accordance with the guidelines set forth in RR: D02-1007 and the software D2PP.

25.1.1 Ethylbenzene - The repeatability and reproducibility values at 95 % confidence level are independent of the mean and are given as follows:

Repeatability (r) = 0.03 vol %

Reproducibility (R) = 0.10 vol %

25.1.2 C8 Aromatics (all components after ethylbenzene) - The repeatability and reproducibility values at a 95 % confidence level are dependent on the results, and are given as follows:

Repeatability (r) = 0.04 x X vol %

Reproducibility (R) = 0.17 x X vol %

where X is the mean of two determinations.

25.1.3 Total Aromatics (toluene, ethylbenzene and C8 aromatics) - The repeatability and reproducibility values at 95 % confidence level are dependent on the results and are given as follows:

Repeatability (r) = 0.02 x X vol %

Reproducibility (R) = 0.17 x X vol %

where X is the mean of two determinations.

25.2 Bias - There was no statistically significant bias of the results compared to expected values for quantitatively prepared standards. Hence, the determination of total aromatics in mineral spirits by capillary gas chromatography as described in this test method has no bias.