14. Report

14.1 Report the following information:

14.1.1 The results in parts per million (by weight) of PCB in the insulating fluid.

14.1.2 The Aroclor(s) used as the standards.

14.1.3 Indicate the type of Aroclor(s) present if possible and desired.

15. Precision and Bias

15.1 The precision, bias, and lower limit of detection have been evaluated by a statistical examination of the results of separate interlaboratory tests of mineral oil and silicone test specimens. The data was generated using packed column chromatography under isothermal conditions on mineral oil and silicone liquid. Additional data was obtained using megabore column chromatography with temperature programming on mineral oil.

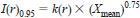

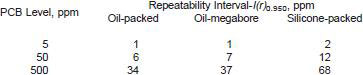

15.2 Repeatability - the difference between successive results obtained by the same operator with the same apparatus under constant operating conditions on identical test material, with normal and correct operation of the test method, was found to vary with PCB level. The repeatability interval at the 95 % confidence level, I(r)0.95, can be represented by:

where k(r) for mineral oil is 0.32 using packed columns and 0.35 using megabore columns; and 0.64 for silicone liquids using packed columns. The repeatability interval of the results of the round robin tests can be typified as follows:

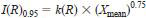

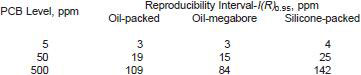

15.3 Reproducibility - The difference between two single and independent results obtained by different operators working in different laboratories on identical test material, with normal and correct operation of the test method, was found to vary with PCB level. The reproducibility interval at the 95 % confidence level, I(R)0.95, can be represented by

where k(R) for mineral oil is 1.03 for packed columns and 0.79 for megabore columns; and 1.34 for silicone liquids using packed columns. The reproducibility interval of the results of these round robin tests can be typified as follows:

15.4 Bias - The bias of this test method was evaluated by comparing the mean value found for each test specimen by several laboratories with the known amount added to that test specimen.

15.4.1 For packed columns, the average bias for oil test specimens was as follows:

15.4.2 For packed columns, the average bias for silicone test specimens was as follows:

15.4.3 The bias when using megabore columns could not be determined from the data of the interlaboratory round robin because the "true values" of the spiked additions were questionable.

15.5 Method Detection Limit - MDL is defined here as the minimum concentration of an analyte that can be reported with 95 % confidence that the value is above zero. The MDL was determined to be 2 ppm PCB in both mineral oil and silicone liquids when using packed columns, and 1 ppm PCB in mineral oil when using megabore columns.

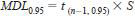

15.5.1 The MDL values have been determined from the reproducibility results of the interlaboratory study on test specimens containing less than 10 ppm PCB. It should be noted that a value of the MDL for an individual laboratory may be calculated from the results of n replicate analyses on a test specimen containing about 5 ppm PCB using the following equation:

where:

t (n-1, 0.95) = student's t value for n-1 and a confidence level of 95 %,

n = number of replicates, and

S = standard deviation of n replicate analyses. A value of the MDL for an individual laboratory may differ from the MDL values reported in these collaborative studies.

16. Keywords

16.1 gas chromatography; PCBs; polychlorinated biphenyls; transformer insulating liquids; transformer mineral oils; transformer silicone liquids