ASTM D4628 standard test method for analysis of barium, calcium, magnesium, and zinc in unused lubricating oils by atomic absorption spectrometry

15. Report

15.1 Report concentrations greater than 0.1 % to three significant figures.

15.2 Concentrations between 0.005 - 0.1 % barium and 0.002 - 0.1 % zinc, calcium, and magnesium are reported to two significant figures.

15.3 Concentrations less than the lower limits in 15.2 shall be reported as less than the appropriate lower limit.

16. Quality Control

16.1 Confirm the performance of the instrument or the test procedure by analyzing a quality control (QC) sample (see 6.7).

16.1.1 When QC/Quality Assurance (QA) protocols are already established in the testing facility, these may be used when they confirm the reliability of the test result.

16.1.2 When there is no QC/QA protocol established in the testing facility, Appendix X1 can be used as the QC/QA system.

17. Precision and Bias

17.1 The precision of this test method as determined by statistical examination of interlaboratory results is as follows:

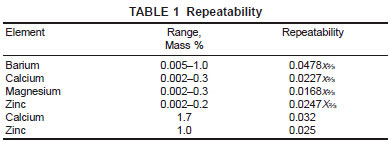

17.1.1 Repeatability - The difference between the two test results, obtained by the same operator with the same apparatus under constant operating conditions on identical test material, would, in the long run, in the normal and correct operation of this test method, exceed the values in Table 1 only in one case in twenty.

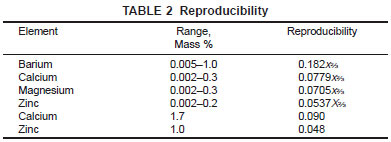

17.1.2 Reproducibility - The difference between two single and independent results obtained by different operators working in different laboratories on identical test materials would, in the long run, in the normal and correct operation of this test method, exceed the values in Table 2 only in one case in twenty.

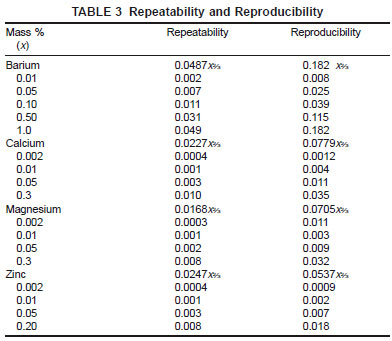

NOTE 11 - The values of these precision estimates for selected values of x are set out in Table 3.

NOTE 12 - The precision data in Section 17 was obtained by using samples containing higher concentration levels of metals and may not be representative of the precision at about 10 ppm concentration levels.

17.2 Bias:

17.2.1 No bias statement can be written because of the lack of suitable reference materials of known composition.

17.2.2 The presence of certain viscosity index improvers can cause a negative bias for one or more elements. In interlaboratory studies, this bias was found to be small relative to the reproducibility of this test method, and the bias was minimized by using smaller sample sizes (for example, a sample size of 0.050 g of a blended oil) for oils that contain viscosity index improvers.

18. Keywords

18.1 additive elements; atomic absorption spectrometry; barium; calcium; lubricating oils; magnesium; zinc