ASTM D4953 Standard Test Method for Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends (Dry Method)

9. Report

9.1 Reporting Results - Report the vapor pressure to the nearest 0.25 kPa (0.05 psi) in kilopascals (pounds-force per square inch) without reference to temperature.

9.2 If the sample was observed to be hazy in 8.4, report the test result as in 9.1, followed by the letter "H".

NOTE 10 - The precision and bias statements have not been determined for hazy samples, since these types of samples have not been evaluated as part of an interlaboratory study.

NOTE 11 - The inclusion of the letter "H" in 9.2 is intended to alert the data recipient that the sample analyzed was hazy. In the event a laboratory has a computer system that is incapable of reporting alphanumeric results in accordance with the requirements in 9.2, it is permissible for the laboratory to report the result obtained as in 9.1, along with a statement or annotation that clearly conveys to the data recipient that the sample analyzed was hazy.

10. Precision and Bias

10.1 The following criteria are to be used for judging the acceptability of results.

NOTE 12 - The following precision data were developed in a 1991 interlaboratory cooperative test program. Participants analyzed sample sets comprised of blind duplicates of 14 types of hydrocarbons and hydrocarbonoxygenate blends. The oxygen content ranged from 0 to 15 % by volume nominal and the vapor pressure ranged from 14 to 100 kPa (2 to 15 psi) nominal. A total of 60 laboratories participated. Some participants performed more than one test method, using separate sample sets for each. Twenty-six samples sets were tested by Test Method D4953, 13 by Test Method D5190 and 27 by Test Method D5191. In addition, six sets were tested by modified Test Method D5190 and 13 by modified Test Method D5191.

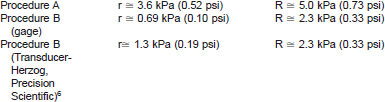

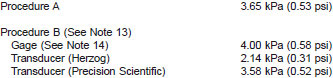

10.1.1 Repeatability - The difference between successive test results obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values in only one case in twenty:

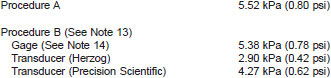

10.1.2 Reproducibility - The difference between two single and independent test results obtained by different operators working in different laboratories on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values only in one case in twenty:

NOTE 13 - The data from the three instruments that performed Procedure B, in the interlaboratory program described in Note 12 yielded precision figures that are different statistically and could not be pooled. Hence these figures are displayed individually.

NOTE 14 - The precision figures are applicable only to gages manufactured by Armaturenbau, GMBH, 0 to 15 psi, Bourdon tube volume of 38 mL nominal. Usage of gauges with other internal volumes may affect the test method precision and bias.

10.2 Bias:

10.2.1 Absolute Bias - Since there is no accepted reference material suitable for determining the bias for the procedures in this test method for measuring vapor pressure of gasoline or gasoline-oxygenate blends, bias cannot be determined. The amount of bias between this test vapor pressure and true vapor pressure is unknown.

10.2.2 Relative Bias - Statistically significant relative biases between Procedures A and Procedure B were observed in the data from the cooperative program described in Note 12. These biases can be corrected by applying the appropriate correlation equation listed below, that calculates a dry vapor pressure equivalent value for Procedure A (DVPE, Procedure A), from values obtained by Procedure B:

10.2.2.1 For Procedure B, gage See Note 13:

DVPE, Procedure A = 1.029 X

10.2.2.2 For Procedure B, transducer, Herzog equipment:

DVPE, Procedure A = 0.984 X

where:

X 5 observed total vapor pressure from Procedure B

10.2.3 No relative bias was observed between procedure A and the Precision Scientific equipment in the data obtained in the interlaboratory program described in Note 12.

10.2.4 Since Test Method D323 was not included in the 1991 interlaboratory test program described in Note 12, no statement can be made regarding the relative bias between any of the methods studied versus Test Method D323 based on data from this study. However, from a 1987 interlaboratory study, no statistically significant bias was observed between Procedure A of this test method and Test Method D323 for samples containing hydrocarbons only or hydrocarbons and methyl t-butyl ether.

NOTE 15 - In the 1991 interlaboratory test program described in Note 12, one jet fuel of type JP-4 was included. Statistically lower repeatability and reproducibility estimates for Procedure B were observed for this particular sample compared to all others in the sample set. Since only one jet fuel was tested in the program, these figures are not intended nor can it be technically considered as a precision statement regarding usage of this method on all jet fuels. This is provided as information only for those who are interestred in the approximate precision of this method when applied to a jet fuel of type JP-4.