12. Calculation and Report

12.1 If the entire fuel sample filtered through a single set of filters then:

12.1.1 Calculate the mass on the test membrane filter,

Mtm, as M2 - M1 in, g.

where:

M2 = mass of the test membrane filter after the filtration (11.4.3) and

M1 = mass of the test membrane filter before the filtration (10.1.5).

12.1.2 Calculate the mass on the control membrane filter,

Mcm, as M4 - M3, g.

where:

M4 = mass of the control membrane filter after the filtration (11.4.3) and

M3 = mass of the control membrane filter before the filtration (10.1.4).

12.1.3 Calculate total particulate contaminant in g/m3 (mg/L) as follows:

[(Mtm - Mcm)/Vf] x 10(6)

where:

Vf = volume of fuel filtered, mL.

12.1.4 Report the particulate contamination to the nearest 0.1 g/m3(mg/L) and the volume of fuel filtered in m3 (L).

12.2 If the fuel sample required more than one set of membrane filters then:

12.2.1 For each set of filters calculate the mass on the test membrane filter, Mtm, as M2(x) - M1(x), in g, where the subscripts 2 and 1 have the same meaning as in 12.1.1 and x indicates the number of the filtration.

12.2.2 For each set of filters, calculate the mass on the control membrane filter, Mcm(x), as M4(x) - M3(x), in g, where the subscripts 4 and 3 have the same meaning as in 12.1.1 and x indicates the number of the filtration.

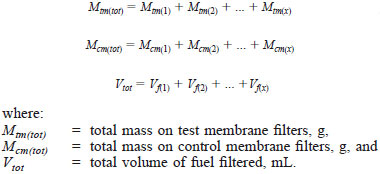

12.2.3 Calculate the total contaminant mass and total volume of fuel filtered for each set of filters as follows:

NOTE 11 - Subscripts 1 to x indicate the number of the filtration.

12.2.4 Calculate the total particulate contaminant in g/m3 (mg/L) as follows:

[(Mtm(tot) - Mcm(tot)/Vtot] x 10(6)

12.2.5 Report the total particulate contamination to the nearest 0.1 g/m3 (mg/L), the total volume of fuel filtered in m3(L), and the total number of filtrations (sets of membranes required).

13. Precision and Bias

13.1 Precision - The precision of this test method was determined in accordance with currently accepted guidelines in Committee D-2 Research Report RR-D02-1007. The cooperative test involved 13 laboratories and nine test fuels. Both grade 1 and grade 2 diesel fuels were used in the testing. The precision data for this procedure were developed by round robin participants using both water aspirated and mechanical vacuum systems with vacuums ranging from 1 to 100 kPa. The information on the precision of this test method was developed with fuels ranging in particulate contamination from approximately 0.3 g/m3 to approximately 25 g/m3. The precision data were obtained by statistical examination of interlaboratory test results using fuels samples of approximately 1 L volume. Results obtained when analyzing samples with volumes significantly different than 1 L may have different precision values.

13.1.1 Repeatability - The difference between successive results obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test method exceed the following values only in one case in twenty.

Repeatability = 0.68 (X)0.5

where:

X = the test result, measured to the nearest 0.1 g/m3

13.1.2 Reproducibility - The difference between the two single and independent results obtained by different operators working in different laboratories on identical test material would, in the long run, exceed the following values only in one case in twenty.

Reproducibility = 1.13 (X)0.5

where:

X = the test result, measured to the nearest 0.1 g/m3

13.1.3 Repeatability and reproducibility values for various values of X are given in Table 1.

13.2 Bias - The procedure given for the determination of Test Method D6217 has no bias because the value of particulate contamination is defined in terms of this test method.

14. Keywords

14.1 diesel fuel; gravimetric determination; kerosine; laboratory filtration; membrane filter; middle distillate fuel; particulate contamination