13. Report

13.1 Report the average value of the two runs, rounded to the nearest 1 µg/kg.

14. Quality Control (QC)

14.1 Confirm the performance of the instrument or the test procedure by analyzing a QC sample (see 8.6). Fig. 2 illustrates the problem of trace level copper migration to sample container walls at ambient temperature which depletes trace organo-copper QC samples with time. Storage in a refrigerated environment (5°C) minimizes the migration of trace level copper.

14.1.1 When QC/Quality Assurance (QA) protocols are already established in the testing facility, these may be used when they confirm the reliability of the test result.

14.1.2 When there is no QC/QA protocol established in the testing facility, Appendix X1 can be used as the QC/QA system.

15. Precision and Bias

15.1 Precision - The precision of this test method (illustrated in Fig. 3) as determined by the statistical examination of the interlaboratory test results is as follows:

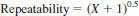

15.1.1 Repeatability - The difference between successive results obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values only one case in twenty:

where:

X = the average of two results in µg/kg.

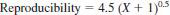

15.1.2 Reproducibility - The difference between two single and independent results obtained by different operators working in different laboratories on identical test material would in the long run, exceed the following values only in one case in twenty:

where:

X = the average of two results in µg/kg.

15.2 Bias - Since there is no accepted reference material for determining bias for this test method, no statement on bias is being made.

16. Keywords

16.1 absorbance units; atomic absorption spectrometer; aviation fuel; copper; graphite furnace; jet fuel; spectrometer