1. Scope

1.1 This test method covers the measurement of the viscosity of drive line lubricants (gear oils, automatic transmission fluids, and so forth) with a constant shear stress viscometer at temperatures from -40 °C to 10 °C after a prescribed preheat and controlled cooling to the final test temperature. The precision is stated for test temperatures from -40 °C to -26 °C.

1.2 The applicability of this particular test method to petroleum products other than drive line lubricants has not been determined.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 This standard uses the SI based unit of milliPascal second (mPa·s) for viscosity which is equivalent to centiPoise (cP).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D2983 Test Method for Low-Temperature Viscosity of Automatic Transmission Fluids, Hydraulic Fluids, and Lubricants using a Rotational Viscometer

D3829 Test Method for Predicting the Borderline Pumping Temperature of Engine Oil

D4684 Test Method for Determination of Yield Stress and Apparent Viscosity of Engine Oils at Low Temperature

D6896 Test Method for Determination of Yield Stress and Apparent Viscosity of Used Engine Oils at Low Temperature

E563 Practice for Preparation and Use of an Ice-Point Bath as a Reference Temperature

E644 Test Methods for Testing Industrial Resistance Thermometers

E1137 Specification for Industrial Platinum Resistance Thermometers

E2877 Guide for Digital Contact Thermometers

2.2 ISO Standards:

ISO 17025 General Requirements for the Competence of Testing and Calibration Laboratories

ISO Guide 34 General Requirements for the Competence of Reference Material Producers

3. Terminology

3.1 Definitions:

3.1.1 apparent viscosity, n - the determined viscosity obtained by the use of this test method.

3.1.2 digital contact thermometer (DCT), n - an electronic device consisting of a digital display and associated temperature sensing probe.

3.1.2.1 Discussion - This device consists of a temperature sensor connected to a measuring instrument; this instrument measures the temperature-dependent quantity of the sensor, computes the temperature from the measured quantity, and provides a digital output. This digital output goes to a digital display and/or recording device that may be internal or external to the device. These devices are sometimes referred to as "digital thermometers".

3.1.2.2 Discussion - PET is an acronym for portable electronic thermometers, a subset of digital contact thermometers (DCT).

3.1.3 Newtonian oil or fluid, n - an oil or fluid that at a given temperature exhibits a constant viscosity at all shear rates or shear stresses.

3.1.4 non-Newtonian oil or fluid, n - an oil or fluid that at a given temperature exhibits a viscosity that varies with changing shear stress or shear rate.

3.1.5 shear rate, n - the velocity gradient in fluid flow.

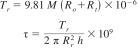

3.1.5.1 Discussion - For a Newtonian fluid in a concentric cylinder rotary viscometer in which the shear stress is measured at the inner cylinder surface (such as the apparatus described in 6.1), and ignoring any end effects, the shear rate is given as follows:

where:

γ = shear rate at the surface of the rotor in reciprocal seconds, s(-1),

Ω = angular velocity, rad/s,

Rs = stator radius, mm,

Rr = rotor radius, mm, and

t = time for one revolution of the rotor, s.

For the specific apparatus being described in 6.1.1,

3.1.6 shear stress, n - the motivating force per unit area for fluid flow.

3.1.6.1 Discussion - For the rotary viscometer being described in 6.1, the rotor surface is the area under shear or the shear area. For this test method, end effects are not considered.

where:

Tr = torque applied to rotor, N·m,

M = applied mass, g,

Ro = radius of the shaft, mm,

Rr = radius of the string, mm,

τ = shear stress at the rotor surface, Pa, and

h = height of the rotor face, mm.

For the dimensions given in 6.1.1,

3.1.7 viscosity, n - the ratio between the applied shear stress and rate of shear, sometimes called the coefficient of dynamic viscosity.

3.1.7.1 Discussion - This value is thus a measure of the resistance to flow of the liquid. The SI unit of viscosity is the pascal second [Pa·s]. The submultiple unit is millipascal seconds (mPa·s).

3.2 Definitions of Terms Specific to This Standard:

3.2.1 calibration oils, n - those oils that establish an instrument's reference framework of apparent viscosity versus speed, from which the apparent viscosities of test oils are determined.

3.2.2 test oil, n - any oil for which the apparent viscosity is to be determined by this test method.

3.2.3 yield stress, n - the shear stress required to initiate flow.

3.2.3.1 Discussion - For Newtonian fluids and some non-Newtonian fluids the yield stress is very small.