11. Laboratory and Engine Test Stand Calibration/Non-Reference Oil Test Requirements

11.1 Calibration Frequency:

11.1.1 To maintain test consistency and severity levels, calibrate the engine and test stand at regular intervals.

11.2 Calibration Reference Oils:

11.2.1 The reference oils used to calibrate T-10 test stands have been formulated or selected to represent specific chemical types or performance levels, or both. They can be obtained from the TMC. The TMC will assign reference oils for calibration tests. These oils are supplied under code numbers (blind reference oils).

11.2.2 Reference Oils Analysis:

11.2.2.1 Do not submit reference oils to physical or chemical analyses for identification purposes. Identifying the oils by analyses could undermine the confidentiality required to operate an effective blind reference oil system. Therefore, reference oils are supplied with the explicit understanding that they will not be subjected to analyses other than those specified within this procedure unless specifically authorized by the TMC. In such cases where analyses are authorized, supply written confirmation of the circumstances involved, the data obtained, and the name of the person authorizing the analysis to the TMC.

11.3 Test Numbering:

11.3.1 Number each T-10 test to identify the test stand number, the test stand run number, engine serial number, and engine hours at the start of the test. The sequential stand run number remains unchanged for reruns of aborted, invalid, or unacceptable calibration tests. However, follow the sequential stand run number by the letter A for the first rerun, B for the second, and so forth. For calibration tests, engine hours shall be zero. For non-reference oil tests, engine hours are the test hours accumulated since last calibration. For example, 58-12A-2H0380-0 defines a test on stand 58 and stand run 12 as a calibration test that was run twice on engine 2H0380 (serial number). A test number of 58-14-2H0380-300 defines a test on stand 58 and stand run 14 as a non-reference oil test on engine 2H0380, which has run 300 hours since the last reference.

11.4 New Laboratories and New Test Stands:

11.4.1 A new laboratory is any laboratory that has never previously calibrated a test stand under this test method, or has not calibrated a test stand within one year from the end of the last successful calibration test. All stands at a new laboratory are considered new stands.

11.4.2 A new stand is a test cell and support hardware, which has never previously been calibrated under this test method, or has not been calibrated within a year from the end of the last successful calibration test on that stand.

11.4.2.1 A new complete engine with EGR kit requires a successful calibration test.

11.4.3 Calibrate a new test stand in accordance with the Lubricant Test Monitoring System (LTMS).

11.5 Test Stand Calibration:

11.5.1 Test Stand Calibration - Perform a calibration test on a reference oil assigned by the TMC after six months have elapsed since the completion of the last successful calibration test. A non-reference test may be started provided at least 1 h remains in the calibration period. An unsuccessful calibration test voids any current calibration on the test stand.

11.5.2 Test Stand/Engine Combination - For reference and non-reference tests, any engine may be used in any stand. However, the engines shall be used in the test stands on a first available engine basis (FIFO). In other words, there shall be no attempt on the part of the test laboratory to match a particular test stand and engine combination for any given test.

11.5.2.1 A new complete engine setup with EGR kit requires a calibration test.

11.5.3 If non-standard tests are conducted on a calibrated test stand, the TMC may require the test stand to be recalibrated prior to running standard tests.

11.6 Test Results - The reference oil test specified test results are average top ring weight loss [milligrams], average cylinder liner wear [micrometers], Δlead [milligrams per kilogram] at EOT, Δlead [milligrams per kilogram] 250 h to 300 h, and average oil consumption (grams per hour). The non-reference oil test specified test result is the Mack Merit Rating.

11.6.1 Average Top Ring Weight Loss - Screen the data for outliers in accordance with Annex A9. Calculate the average top ring weight loss, excluding any outliers, and report the data on the appropriate forms.

11.6.2 Average Cylinder Liner Wear - Screen the data for outliers in accordance with Annex A9. Calculate the average cylinder liner wear step, excluding any outliers, and report the data on the appropriate forms.

11.6.3 ΔLead at EOT - ΔLead at EOT results are adjusted to account for any upper rod bearing weight loss outliers.

11.6.3.1 Calculate the measured average upper rod bearing weight loss and report the value on the appropriate form.

11.6.3.2 Use Practice E178, two-sided test at a 95 % significance level, to determine if any rod bearing weight loss values are outliers. Report the outlier screened average upper rod bearing weight loss on the appropriate form. If no outliers were identified, this value will be identical to the measured value calculated in 11.6.3.1.

11.6.3.3 For connecting rod bearing batch codes A through G, calculate Δlead according to the following:

Δlead = (lead300 - leadNEW) x (OABWLU/ABWLU)

where:

lead300 = lead content of the 300 h oil sample, mg/kg,

leadNEW = lead content of the new oil sample, mg/kg,

ABWLU = as measured upper rod bearing weight loss, mg, and

OABWLU = outlier screened upper rod bearing weight loss, mg.

Report the calculated Δlead at EOT value on the appropriate forms.

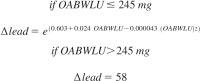

11.6.3.4 For connecting rod bearing batch code J, calculate Δlead according to the following:

where:

OABWLU = outlier screened upper rod bearing weight loss, mg.

11.6.3.5 Report the calculated Δlead at EOT value on the appropriate forms.

11.6.4 ΔLead 250 h to 300 h:

11.6.4.1 For connecting rod bearing batch codes A through G, calculate the ΔLead 250 h to 300 h by subtracting the lead value at 250 h from the lead value at 300 h.

11.6.4.2 For connecting rod bearing batch code J, calculate the ΔLead 250 h to 300 h according to the following:

ΔLead 250 h to 300 h = -5.9 + 0.044 (ir300 - ir250) + 0.070 OABWLU

where:

ir300 = oxidation value of the 300 h oil sample

ir250 = oxidation value of the 250 h oil sample

OABWLU = outlier screened upper rod bearing weight loss, mg.

11.6.4.3 Report the results on the appropriate forms.

11.6.5 Oil Consumption:

11.6.5.1 Report the oil consumption, as calculated in 10.5, on the appropriate form.

11.6.6 Mack Merit Rating:

11.6.6.1 Report the Mack Merit Rating as calculated in Annex A10.

11.7 Reference and Non-Reference Oil Test Requirements:

11.7.1 All operationally valid tests shall produce a TGA soot level of 5.0 % +/- 0.3 % at 75 h. Any test that misses the 75 h soot window is considered operationally invalid. A laboratory should terminate a test that has missed the 75 h soot window.

11.7.1.1 Injection timing can be adjusted anytime within the first 75 h to meet the 75 h soot window. However, during the first 75 h, do not adjust injection timing more than +/- 5° from the initial injection timing.

11.7.2 Calibration acceptance is determined in accordance with the LTMS as administered by the TMC.

11.8 Non-Reference Oil Test Result Severity Adjustments:

11.8.1 This test method incorporates the use of a severity adjustment (SA) for non-reference oil test results. A control chart technique, described in the LTMS, has been selected for identifying when a bias becomes significant for average top ring weight loss, average cylinder liner wear, Δlead at EOT, Δlead 250 h to 300 h, and oil consumption. When calibration test results identify a significant bias, determine an SA according to LTMS. Report the SA value on the appropriate form, Test Results Summary, in the space for SA. Add this SA value to non-reference oil test results, and enter the adjusted result in the appropriate space. The SA remains in effect until a new SA is determined from subsequent calibration test results, or the test results indicate the bias is no longer significant. Calculate and apply SA on a laboratory basis.

11.9 Donated Reference Oil Test Programs - The surveillance panel is charged with maintaining effective reference oil test severity and precision monitoring. During times of new parts introductions, new or re-blended reference oil additions, and procedural revisions, it may be necessary to evaluate the possible effects on severity and precision levels. The surveillance panel may choose to conduct a program of donated reference oil tests in those laboratories participating in the monitoring system, in order to quantify the effect of a particular change on severity and precision. Typically, the surveillance panel requests its panel members to volunteer enough reference oil test results to create a robust data set. Broad laboratory participation is needed to provide a representative sampling of the industry. To ensure the quality of the data obtained, donated tests are conducted on calibrated test stands. The surveillance panel shall arrange an appropriate number of donated tests and ensure completion of the test program in a timely manner.

11.10 Adjustments to Reference Oil Calibration Periods:

11.10.1 Procedural Deviations - On occasions when a laboratory becomes aware of a significant deviation from the test method, such as might arise during an in-house review or a TMC inspection, the laboratory and the TMC shall agree on an appropriate course of action to remedy the deviation. This action may include the shortening of existing reference oil calibration periods.

11.10.2 Parts and Fuel Shortages - Under special circumstances, such as industry-wide parts or fuel shortages, the surveillance panel may direct the TMC to extend the time intervals between reference oil tests. These extensions shall not exceed one regular calibration period.

11.10.3 Reference Oil Test Data Flow - To ensure continuous severity and precision monitoring, calibration tests are conducted periodically throughout the year. There may be occasions when laboratories conduct a large portion of calibration tests in a short period of time. This could result in an unacceptably large time frame when very few calibration tests are conducted. The TMC can shorten or extend calibration periods as needed to provide a consistent flow of reference oil test data. Adjustments to calibration periods are made such that laboratories incur no net loss (or gain) in calibration status.

11.10.4 Special Use of the Reference Oil Calibration System - The surveillance panel has the option to use the reference oil system to evaluate changes that have potential impact on test severity and precision. This option is only taken when a program of donated tests is not feasible. The surveillance panel and the TMC shall develop a detailed plan for the test program. This plan requires all reference oil tests in the program to be completed as close to the same time as possible, so that no laboratory/stand calibration is left in an excessively long pending status. In order to maintain the integrity of the reference oil monitoring system, each reference oil test is conducted so as to be interpretable for stand calibration. To facilitate the required test scheduling, the surveillance panel may direct the TMC to lengthen and shorten reference oil calibration periods within laboratories such that the laboratories incur no net loss (or gain) in calibration status.