10. Procedure

10.1 Position a new sheet of filter paper in the filter paper holder and place it on the bench.

10.2 Shake the sample vigorously until the sample is adequately homogenized and no sediment is adhered to the bottom or sides of the container.

10.3 With the positive displacement pipette, sample 20 µl of sample, wipe the outer surface of the pipette tip from excess of oil, and inject the sample in the center of the hole provided in the holder.

10.4 Ifseveral different samples are tested, repeat steps 10.2 and 10.3 with all samples to be tested (Fig. 5). Several different oil spots can be prepared on the same sheet. If this is the case, it is recommended to write the sample identification under each spot.

10.5 The paper holder with the paper sheet is then placed in horizontal position for 60 min +/- 2 min in a laboratory drying oven adjusted to 80 °C.

10.6 After 60 min +/- 2 min, remove the paper holder from the oven. (Warning - The paper holder surface is at 80 °C. Use protecting gloves to take the holder out of the oven.)

10.7 The paper filter is extracted from the holder. After the 60 min drying phase at 80 °C, the oil spot may continue its expansion. In order to obtain precise results, the oil spots must be analyzed within a maximum of 60 min after removal from the oven.

10.8 Key in all sample details. Position the oil spot in front of the CCD camera and the image of the oil spot is displayed. The oil spot must be positioned within the displayed red circle. Press the test key to initiate the test. For more details, refer to the instruction manual of the apparatus manufacturer.

10.9 Once the test is initiated, the following steps will be achieved:

10.9.1 Step 1 - Oil Spot detection and size measurement.

10.9.1.1 The software determines the edges and the center of the oil spot. r1 and r2 in Fig.6 are determined by converting in mm the number of pixels on r1 and r2 lines. The diameter of the oil spot is determined by the addition of r1 + r2.

10.9.2 Step 2 - Contamination Index - IC calculation.

10.9.2.1 The contamination level (IC) is determined by analyzing the oil spot opacity. The software determines the level of gray (from 0 to 255) of each pixel included in the oil spot. The oil spot opacity is the sum of all opacities of all pixels included in the oil spot image divided by the total number of pixels of the oil spot image. Using an established correlation table, the software determines the IC corresponding to the measured opacity. The IC measuring limits are: 0 % to 4.8 %.

10.9.3 Step 3 - Merit of Dispersancy - MD calculation.

10.9.3.1 To determine MD, the software needs to calculate two intermediary parameters, DB (DB comes from the French term Démérite Brut, which means gross demerit) and ratio.

10.9.3.2 Homogeneity of soot distribution within the oil spot is assessed by the DB value. The distribution of the particles in the oil spot is assessed by the ratio value. The DB and the ratio values are not reported. Combination of both DB and ratio gives the value of the merit of dispersancy (MD).

MD = (1 - DB)·(Ratio·100)

10.9.3.3 To calculate DB and ratio, the software determines 16 zones in the oil spot with a width of 1 mm each, which corresponds to the ideal reference oil spot of 32 mm diameter.

10.9.3.4 Based on the assumption that the oil spot has a symmetrical form, the processing of the image is performed in two rectangular areas with a length of 16 mm and a height of 11 pixels, which is approximately 1 mm (Fig. 7).

10.9.3.5 Because the oil spot could be oval, the calculation is done separately for X and Y coordinates (blue rectangles).

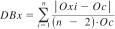

10.9.3.6 DB is calculated as follows:

where:

n = number of pixels per mm,

Oxi = opacity of zone i on X direction, and

Oc = overall average oil spot opacity.

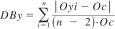

where:

n = number of pixels per mm,

Oyi = opacity of zone i on Y direction, and

Oc = overall average oil spot opacity.

DB = (DBx + DBy)/2

10.9.3.7 The ratio is calculated as follows (Fig.8):

10.9.3.8 The median opacity is calculated for the X and Y axis respectively.

10.9.3.9 Beginning from the oil spot center, the opacity value of each pixel is cumulated until the sum exceeds Om where:

10.9.3.10 The distance between the oil spot center and the point where the sum is equal to Om is called Rmx for X axis and Rmy for Y axis.

10.9.3.11 The ratio is a measure of how well balanced the contamination matter is through the oil spot:

Ratio = 2·(Rmx + Rmy)/2 Rt

10.9.3.12 If the ratio is equal to one, the distribution of particles is considered homogeneous throughout the oil spot.

10.9.3.13 The lower the ratio value, the closer the black sooty particles are to oil spot center.

10.9.3.14 MD is then calculated as follows:

MD = (1 - DB)·(Ratio·100)

10.9.4 Step 4 - Weighted Demerit - DP calculation (DP comes from the French term Démérite Pondéré, which means weighted demerit).

10.9.5 DP is a combined performance rating (overall note), which is helpful for trend condition monitoring of the performance of the lubricant. Two parameters are used for this calculation, the merit of dispersancy (MD) and the contamination index (IC).

10.9.6 DP is calculated as follows:

DP = (100 - MD)·IC