X1.1 Introduction

X1.1.1 This technique to prevent surface skin formation when testing flash point of asphalts by Test Method D92 was developed by Imran Hussami of Frontier El Dorado Refining Company.

X1.2 Materials Required

X1.2.1 Filter Paper, qualitative, No. 417 (or equivalent), 7.5cm diameter.

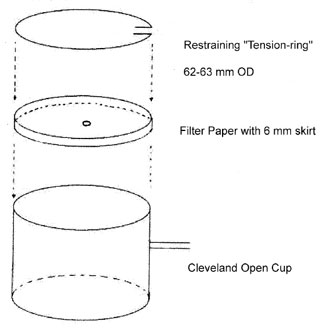

X1.2.2 Restraining Tension-ring, metal wire, circular, but with its 15mm straight ends folded inwards, parallel to each other (see Fig. X1.1). Dimensions: wire about 2mm thick, 62 to 63 outside diameter with bent ends 15mm apart along the circumference of the circle. Total length of wire is about 210mm. An ordinary metal coat hanger or similar material can be used to make the tension-ring.

X1.2.3 Single-hole Punch, (or equivalent) capable of making a 6mm diameter hole in the center of the filter paper.

NOTE - Use of this alternate technique may cause bubbling in some samples. Bubbling could interfere with automatic flash detection devices, and it also may cause a slower heating rate in some samples.

X1.3 Procedure

X1.3.1 Determine the center of the filter paper by means of a ruler. Using the single-hole punch, punch a 6-mm diameter hole in the center of the 7.5cm diameter qualitative filter paper.

X1.3.2 Curl up the sides of the filter paper, about 6mm all around, and place it in the base of the Cleveland open cup flash point test cup, with the 6-mm skirt facing upward (see Fig. X1.1).

X1.3.3 Place the restraining tension-ring snugly over the curved portion of the filter paper in the base of the cup. (The tension-ring prevents the filter paper from moving upward during the test.)

X1.3.4 Fill the cup with the sample 4 to 5 mm below the filling mark (this is to compensate for the sample that is absorbed by the filter paper which will be released during the test). (Warning - Filling all the way to the filling mark could produce premature flash point results.)

X1.3.5 Start the test either using a manual tester or an automatic unit (following manufacturer's instructions) and determine the flash point.

X1.3.6 Report the flash point corrected for bariometric pressure to the nearest 1°C.