ASTM E2412 Standard Practice for Condition Monitoring of In-Service Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR) Spectrometry

6. Apparatus

6.1 Required Components:

6.1.1 Fourier Transform Infrared Spectrometer (FT-IR) - Instrument is configured with a source, beamsplitter and detector to adequately cover the mid-infrared range of 4000 cm(-1) to 550 cm(-1). Most work has been done on systems using a room temperature deuterated triglycine sulfate (DTGS) detector, air-cooled source and Germanium coating on Potassium Bromide (Ge/KBr) beamsplitter. Alternate source, beam-splitter and detector combinations covering this range are commercially available but have not been investigated for use in this practice. Other detectors may be suitable but should be used with caution. In particular, liquid nitrogen cooled Mercury Cadmium Telluride (MCT) detectors are known to exhibit significant nonlinearities.

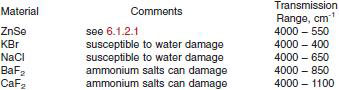

6.1.2 Infrared Liquid Transmission Sampling Cell - Sampling cells can be constructed of zinc selenide (ZnSe), barium fluoride (BaF2), potassium bromide (KBr), or other suitable window material, with a pathlength of 0.1 mm (100 µm), parallel (<0.5° variance) cell spacer. Acceptable path-length ranges are from 0.080 to 0.120 mm. Outside this range, poor sensitivity or data nonlinearity can occur. For the data provided in this document, the cells used were ZnSe, NaCl, or KBr as the measurements ranged from 4000 cm(-1) to 700 cm(-1). Some cell material information is given below.

Results should be corrected to 0.100 mm pathlength to account for cell path variation and improve data comparison to other instruments using this practice.

6.1.2.1 Due to the large refractive index change when the infrared beam passes from air into the ZnSe windows, fringe reduction is necessary to provide consistent results. Fringe reduction can be achieved electronically, optically or mechanically for ZnSe cells. For further explanation, see Appendix X1. Care should be taken in selecting window materials to ensure that the desired parameters can be measured within the transmission region of that material and compatibility with the specific application; for example, salt windows (KBr, NaCl, KCl) can be used and may not require fringe correction but are susceptible to damage from water contamination in the oil. Coates and Setti (3) have noted that oil nitration products can react with salt windows, depositing compounds that are observed in later samples.

6.1.3 Cell Flushing/Cleaning Solvent - The ideal solvent to flush the cell between samples to minimize carryover should have no significant absorption in the condition monitoring areas of interest and should dry quickly when air is pumped through the system. Typical wash solvents used for common petroleum and some synthetic lubricants are technical grade, light aliphatic hydrocarbons such as heptane or cyclohexane. Other solvents may be required for more specialized synthetic lubricants. Health and safety issues on using, storing, and disposing of these solvents will not be covered here. Local regulations and Material Safety Data Sheets (MSDS) should be consulted.

6.2 Optional Components:

6.2.1 Sample Pumping System - A pumping system capable of transporting the sample to the transmission cell, emptying the cell and flushing the cell between samples may be used. Many commercial vendors offer various configurations of pump types, tubing and transmission cells for this type of application. It should be noted that non-homogeneity might occur if the oils are left standing for too long.

6.2.2 Filter - The use of a particulate filter (for example, 0.090 mm) to trap large particles is strongly recommended to prevent cell clogging when a pumping system is used. If a particulate filter is not used, the cell should be back-flushed regularly to prevent clogging.

6.2.3 Sealed Sample Compartment - The system configuration should be consistent with preventing harmful, flammable or explosive vapors from reaching the IR source.

6.2.4 Hydrocarbon Leak Alarm - When a sample pumping system is used, an independent flammable vapor sensor and alarm system should be used to alert the operator when a leak occurs in the tubing, connectors or transmission cell. This alarm system is strongly recommended when a pumping system is used to pump samples and wash solvents into an enclosed area.

6.2.5 Check Fluid - A check fluid or quality control fluid can be analyzed as needed for individual laboratory quality control and procedure issues and for comparison to other laboratories. One IR manufacturer has used heptane. A check sample should be a material that provides consistent results using the methods presented in the annexes to this practice. The purpose of this quality control fluid is to verify proper operation of the FT-IR spectrometer/transmission cell combinations, as well as any associated sample introduction and cleaning hardware.