Foaming and entrained air are air contamination in lubricant system.

Causes of air contamination (foam & air bubbles)

(1) Low surface tension

Oxidation

Solvents

Polar contaminants

Certain additives

Water contamination

(2) Small (Crushed) air bubbles

High oil viscosity

Too much defoamant

Solid suspensions that seed air bubbles

Oil and Machine Failure by Air Contamination

Air contamination (foam and entrained air or air bubbles) in lubricating oil can have negative effects on the machine and the lubricant.

Air contamination (Foam and Air Bubbles) can damage a machine by

(1) Incomplete of oil films in bearing, gears, etc. Component wear due to reduced viscosity.

(2) Inability to maintain oil pressure (low oil pressure cause switch trip)

(3) Poor hydraulic, turbine, pump performance or failure (such as cavitation, erratic operation control, loss of precision control, vibration, etc)

Air contamination (Foam and Air Bubbles) can damage lubricating oil by

(1) Premature of lubricant degradation (increasing the rate of oxidation and thermal degradation)

(2) Drastic increase temperature due to microdieseling

(3) Reducing its heat transfer coefficient and ability

(4) Depleting additives

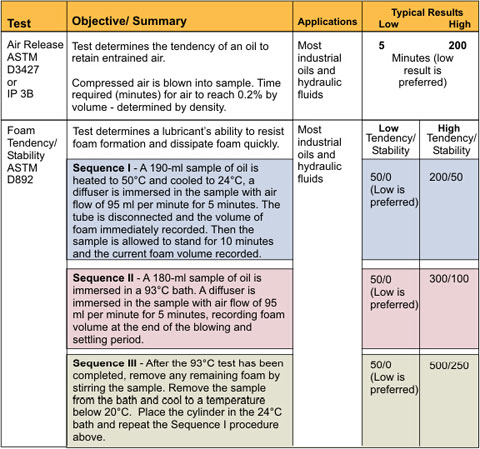

Foaming Characteristic (ASTM D892) and Air Release (ASTM D3427)