Model: GC2010A Trace Hydrocarbon Analyzer

Air separation method is currently a main solution for industrial production of oxygen, nitrogen and argon. However, due to air pollution, the raw materials containing hydrocarbon enters into air separation equipment, which directly threats the safe production. If concentrations of hydrocarbon exceeds the limits, the air separation equipment will explode consequently. Therefore, it is very important to know the compounds and concentrations of hydrocarbon to properly evaluate and control production process.

1 Application

GC2010A trace hydrocarbon analyzer is an automated gas chromatograph can automatically and continuously analyze trace hydrocarbon compounds and concentrations in liquefied oxygen, liquefied air during air separation process. Real-time monitors variation of concentrations of C1 - C4. Provides important data for safety operation of air separation equipment. It is also used in petrochemical industry, steel industry, gas industry and refinery plant to measure hydrocarbons.

2 Features

• Automatic sampling and injecting

• Unattended automatically measure hydrocarbons in liquified oxygen

• Fast peak identification and results processing

• Long lifetime column

• High sensitivity detector with low noise

3 Technical specification

• Start-up stabilizing time: <1 hour

• Temperature control range: room temperature - 400℃

• Temperature control accuracy: ±0.1℃

• Normal operating stability of instrument

Baseline noise: ≤ ±0.03mv

Baseline drift: ≤ ±0.1mv/30min

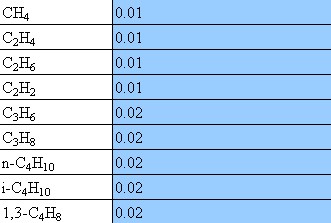

4 Minimum detection concentration (Unit: ppm)