Section 2. Test methods

5 Test methods

5.1 Appearance

Appearance shall be evaluated by examining a representative sample of the liquid in transmitted light under a thickness of approximately 10 cm, at ambient temperature.

5.2 Density

Any recognized test method may be used. The method to be used in case of dispute shall be that given in ISO Standard 3675.

Density shall be measured at 20 °C or converted to 20 °C by the formula:

ρ20 = ρt[1 + X(t - 20)]

where:

ρ20 is the density at 20 °C

t is the temperature in degrees Celsius

ρt is the density measured at temperature t

X is a correction factor: 65 x 10(-5) (approximate value)

For greater accuracy the correction factor listed in ISO Recommendation R/91-1 should be used.

5.3 Kinematic viscosity

Kinematic viscosity shall be measured by the method given in ISO Standard 3104.

5.4 Flash-point

Flash-point shall be determined either with a closed cup or with an open cup.

5.4.1 Closed cup method

Flash-point shall be determined according to ISO Standard 2719.

5.4.2 Open cup method

Flash-point shall be determined according to ISO Standard 2592.

5.5 Pour-point

Pour-point shall be determined according to ISO Standard 3016.

5.6 Cloud-point

Cloud-point shall be determined according to ISO Standard 3015.

5.7 Neutralization value

5.7.1 Reagents

a) Standard alcoholic potassium hydroxide (KOH) solution 0,1 mol/l.

b) Toluene, sulphur-free.

c) Azeotropic ethanol (boiling-point 78,2 °C).

d) Standard hydrochloric acid solution (HCl) 0,1 mol/l.

e) Alkali blue indicator solution: 2 g of alkali blue 6 B are dissolved in 100 ml of azeotropic ethanol containing 1 ml hydrochloric acid 0,1 mol/l. After 24 h, titrate to check whether the indicator has been sufficiently sensitized. The indicator is satisfactory if the colour changes distinctly from blue to red, comparable to that of 10 % solution of cobalt nitrate [Co(NO3)2·6H2O].

Should sensitization be insufficient, repeat the addition of 0,1 mol/l HCl and check again after 24 h. Continue until sensitization is satisfactory. Filter and store in a brown bottle in the dark.

5.7.2 Procedure

Weigh 20 g of the sample to the nearest 0,05 g into a 250 ml stoppered conical flask.

To a mixture of 60 ml of toluene and 40 ml of ethanol in a second conical flask add 2 ml of indicator solution. Neutralize the solution with 0,1 mol/l KOH alcoholic solution until a red colour comparable to that of a solution of 10 % cobalt nitrate [Co(NO3)2·6H2O] is obtained and persists for at least 15 s.

Add this solution to the sample, swirl and immediately titrate at a temperature not above 25 °C with 0,1 mol/l KOH solution to the above end-point.

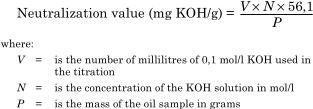

The neutralization value is calculated from the expression:

5.8 Water content

Water content shall be determined according to IEC Publication 814 or IEC Publication 733.

5.9 Corrosive sulphur

Corrosive sulphur shall be determined according to ISO Standard 5662.

5.10 Anti-oxidant additives

Methods for the detection and quantitative determination of specified anti-oxidant additives are described in IEC Publication 666.

5.11 Breakdown voltage

5.11.1 Breakdown voltage shall be determined

according to IEC Publication 156.

5.11.2 When breakdown voltage is to be determined on a treated oil sample the following procedure shall be used to remove moisture and particulate contaminants present in the original sample.

A sufficient oil volume is heated to approximately 60°C, then filtered hot under a vacuum of about 2,5 kPa through a sintered glass filter of grade 10 porosity (ISO Standard 4793). The filtrate is cooled in a dessicator and used immediately to determine breakdown voltage.

NOTE Filtration can be done equally well at ambient temperature, but under lower pressure (e.g. 0,5 kPa).

5.12 Dielectric dissipation factor

Dielectric dissipation factor shall be determined at 90 °C according to IEC Publication 247.

NOTE When oil as delivered shows a dielectric dissipation factor exceeding the limits specified in Sheet 1, a repeat measurement made on a sample treated as indicated in Sub-clause 5.11.2 will show if contaminants are removed by a relatively mild treatment.

5.13 Stability under electrical stress and ionization (gassing)

The gassing shall be determined by Method A of IEC Publication 628.