3 Evaporative stripping method for high viscosity liquids

3.1 Field of application

This method is designed for the determination of water in unused insulating liquids having viscosity greater than 100 mm2/s at 40 °C. This method is mainly applicable to water concentration above 2 mg/kg.

NOTE Alternatively, high viscosity liquids may also be analyzed for water content by the method in clause 2 after dilution with a suitable solvent. Precision for a dilution procedure will be affected by the degree of dilution and the water content and viscosity of the chosen solvent.

3.2 Outline of the method

A known amount of the insulating liquid is heated in a closed vessel located next to the Karl Fischer apparatus. The water evolved is quantitatively transferred into the titration vessel by a stream of dry nitrogen gas where coulometric titration is performed.

3.3 Apparatus and reagents

The block diagram of the apparatus is illustrated in Figure 3 and consists of the following items:

- titrator: automatic coulometric Karl Fischer (see 2.3);

- evaporator: glass vessel, 100 ml capacity; nitrogen inlet tube, 1,25 mm inside diameter (see Figure 4);

- heater: clear, transparent electro-conductive glass heater;

- temperature controller: automatic control, accuracy +/- 2 °C;

- carrier gas: nitrogen gas, commercial grade, less than 10 4l/l water;

- desiccants for carrier gas: one silica gel column plus two phosphorus pentoxide columns;

- reagents as listed in 2.4.

NOTE When interfering compounds are present, the need for suitable reagents in the titrator is of equal importance as for direct sample injection.

3.4 Procedure

a) Operate the Karl Fischer titrator as per procedures specified in 2.5.

b) Inject a sufficient volume (approximately 10 cm 3 ) of base oil into the evaporator vessel via the septum of the injection plug so as to immerse the tip of the nitrogen inlet tube to permit bubbling of the gas. This base oil may be the insulating liquid to be tested or any other miscible oil which does not react with the sample and of similar viscosity at the operating temperature to the oil being analyzed.

c) Set the temperature of the evaporator unit to 130 °C +/- 5 °C and allow the temperature to stabilize. Purge the whole system with dry nitrogen gas at a flow rate of 50 cm3/min to 200 cm3/min to thoroughly dry the base oil as indicated by a low and stable reading of background current.

d) Turn on the titration switch. Run two blanks of 10 min each on this initial base oil by following steps f) and g) of the procedure. If the two blanks are within 5 μg of water, take the average blank value (m1). If the two blanks differ by more than 5 μg of water, further drying of the base oil may be needed.

e) Introduce a suitable quantity of the insulating liquid (M) into the evaporator vessel using a syringe (minimum needle size: 2 mm inside diameter) or other suitable sampler. Weigh the syringe before and after liquid injection to obtain the accurate mass of sample. Use a 10 g sample for water contents greater than 10 mg/kg and a 20 g +/- 5 g sample for water contents less than 10 mg/kg.

f) Turn off titration switch on main unit, or otherwise inhibit titration, for a 10 min period to allow moisture released in the evaporator to accumulate in the titration cell.

g) After 10 min, turn on the titration switch and allow to titrate to the end-point.

h) Read the quantity of water titrated (m 2 ) from the Karl Fischer apparatus.

NOTE When the water contents are higher than 50 mg/kg and/or the mass of sample is 10 g, there is the possibility that complete evaporation of the water has not taken place. In such cases, the analysis should be repeated as in steps e) to h) but using an increased titration delay time and/or a lower amount of oil. With some designs of titrator this purpose can be achieved by setting the delay time sufficiently long.

i) It is good practice to confirm stable operating conditions by carrying out another blank determination for a 10 min period. If the value determined is within 5 μg of the original blank value m1, no further titration is needed.

j) Carry out a duplicate determination.

NOTE In the case of routine tests steps d) and i) may be omitted and in steps f) and g) the 10 min may be reduced to 1 min.

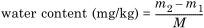

3.5 Calculation of water content

For each individual determination, calculate the water content as follows:

where

m1 is the average blank reading in micrograms (μg);

m2 is the mass of water titrated during sample analysis in micrograms (μg);

M is the mass of the sample in grams (g)

3.6 Report

The water content of the insulating liquid sample is expressed as the average of duplicate determinations to the nearest integer in milligrams per kilogram.