EXPLANATION

The low-temperature, low-shear, rheological behavior of an engine oil plays a major role in determining whether the oil will flow to the inlet screen and then to the oil pump in sufficient quantities that the oil pump will be able to supply lubricant to the critical areas of the engine shortly after starting. Without such supply, engine failure can occur within a few minutes. This test method permits the relatively rapid determination of the suitability of an engine oil to flow to the pump inlet screen at low temperatures. Critical pumpability temperatures can be determined readily without deliberate choice of single or multiple test temperatures since all engine oils are tested in the same scanning manner over a -5 to -45° C temperature range. Applicability to petroleum products other than engine oils has not been determined. The three pumpability tests - Test Methods D3829, D4684, and this one, Test Method D5133 - use different shear stress and shear rates, and this can lead to differences in measured viscosity by these test methods among some test oils.

TEST SUMMARY

An oil, preheated to a specified temperature for a specified minimum time, is placed in a special test cell that is in turn immersed in temperature programmable liquid bath. The test cell is calibrated with calibration oil over the range of viscosities and temperatures of interest. The viscosity of the sample oil is then measured continuously over the chosen temperature range using a rotor turning within the test cell as the temperature is initially lowered, at l ° C/h, through the temperature range of interest. The torque required to shear the oil over the temperature range spanned during the test is continuously recorded. This torque record is used to calculate the oil viscosity. The critical pumpability temperature is stated to be that temperature at which the viscosity exceeds the value of critical pumpability viscosity.

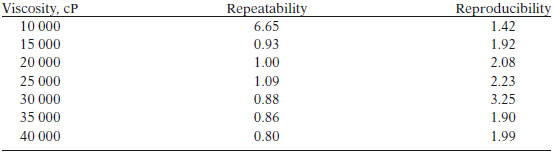

TEST PRECISION

The bias of this test method has not been determined.