Transformer oil dissolved gas analysis is a useful, predictive and effective way for evaluating transformer health. The breakdown of electrical insulating material and related components inside a transformer generates gases within the transformer. Therefore, the identity of these gases being generated is very important to maintenance of transformer.

The two principal causes of gas formation within an operating transformer are electrical disturbances and thermal decomposition All transformer generate gases to some extent at normal operating temperatures. Insulating mineral oil for transformers are mixtures of many different hydrocarbon molecules, and the decomposition processes for these hydrocarbons in thermal or electrical faults are complex. The fundamental chemical reactions involve the breaking of carbon-hydrogen and carbon-carbon bonds. During this process, active hydrogen atoms and hydrocarbon fragments are formed. These fragments can combine with each other to form gases: hydrogen(H2), methane(CH4), acetylene(C2H2), ethylene(C2H4), and ethane(C2H6). Further, when cellulose insulation is involved, thermal decomposition of electric faults produce methane(CH4), hydrogen(H2), carbon monoxide(CO), and carbon dioxide(CO2). The gases listed above are generally referred to as Key Gases. Except for CO2, other gases are generally considered as combustible gases.

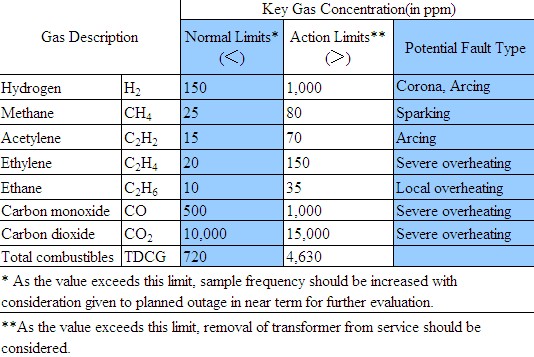

All these gases may indicate the existence of any one or a combination of thermal, electrical faults. And the concentrations of the individual dissolved gases are used to evaluate the thermal history of the transformer internals to suggest any past or potential faults within the transformer. Below is a table which has been derived from ANSI/IEEE C57.104. The suggested action levels for key gas concentrations are also provided:

When dissolved gas analysis results include a sharp increase in key gas concentration levels, and/or normal limits have exceeded, it is suggested that an additional sample and analysis be performed to confirm the previous evaluation and determine if the key gas concentrations are increasing. As key gas concentration levels approach the action levels, consideration should be given to taking the transformer out of service for further testing and inspection.

Once key gas concentrations have exceeded normal limits, other analysis techniques, should be considered for determining the potential problem within the transformer. The techniques involve calculating key gas ratios and comparing these ratios to suggested limits. Some of the most commonly used techniques include the application Doernenburg ratios, Rogers ratios, and Duval Triangle model.

(Originally written by Lynn Hamrick. Thanks for his study on this topic.)